Downloads

The Ultimate Guide to Preventive Maintenance

In this guide, we'll take you through everything you need to know to start or improve a preventive maintenance program at your organization .

Unlock Your All Access Pass

Introduction

Preventive maintenance is extremely important for making sure your equipment runs as smoothly as possible at all times. It’s a little like your car; you want to maintain your vehicle before the issues occur, so you’re not stranded on the side of the road.

Some facilities might see the cost of a preventive maintenance program as excessive, but thinking like this is a bit short-sighted. The amount of money a good preventive maintenance program can save on equipment downtime, emergency maintenance work, and lost profit due to failed assets more than outweighs the initial investment of implementation.

In this guide, we’ll take you through everything you need to know to start or improve a preventive maintenance program at your organization.

What Is Preventive Maintenance?

The goal of preventive maintenance, also spelled preventative maintenance, is to increase asset lifetime by preventing excess depreciation and impairment or untimely breakdown. This maintenance includes, but is not limited to, adjustments, cleaning, lubrication, repairs, and parts replacements.

Due to the unique needs of different assets, the type and amount of preventive maintenance required varies. Because of this, it can be challenging to establish a successful preventive maintenance program. However, a good rule of thumb is to start with a time-based preventive maintenance program.

Types of Preventive Maintenance

Any maintenance that is not reactive maintenance is preventive maintenance. And there are many different types of preventive maintenance that require different types of technology and expertise. Two common types of preventive maintenance include:

Calendar-Based Maintenance: A recurring work order is scheduled for when a specified time interval is reached in the comuterized maintenance management system (CMMS).

Usage-Based Maintenance: Meter readings are used and logged in the CMMS. When a specific unit is reached, a work order is created for routine maintenance.

The Preventive Maintenance Model

There are four critical factors in a preventive maintenance program that you have to consider. Your answers to the questions will help you understand whether you need a preventive maintenance schedule in place.

How bad is the worst case scenario?

What is the likelihood of a breakdown?

How much will it cost?

Is there a preventive task that can mitigate the failure?

To help you answer these questions, let's look at three examples.

Three Examples of Preventive Maintenance

First, there are two examples of when you shouldn’t and should perform preventive maintenance. However, there are instances where the line is not as clear. Below, we’ll expand on these examples and offer a third “grey area” case in an effort to help you decide.

1. Preventive Maintenance Is Not Needed

Case: Replace light bulbs in the women’s bathroom every year

The worst-case scenario is that a bulb burns out. The bathroom has multiple lights, so worst-case, not so bad. The likelihood of a bulb going out at some point is pretty high, and the cost to do preventive maintenance on these lights every year is quite high given the relative impact it has. With that said, do you think it makes sense to do preventive maintenance on bathroom lights? Probably not. Let’s just wait until a bulb burns out and get a work request to replace it.

2. Preventive Maintenance Is Needed

Case: Lube chains for critical equipment every seven days

If there is a breakdown on a critical piece of equipment, that could stop production. This could mean a loss of thousands, maybe millions, of dollars. Also, the likelihood of a breakdown is probably very high because the equipment is constantly running. It’s probably a good idea to do preventive maintenance in this case.

3. Preventive Maintenance Is Questionable

Case: Change HVAC filter every six months

The worst case is that the HVAC machine goes down. The likelihood of this is questionable. HVAC machines will still run with a clogged filter, but efficiency is reduced, causing increased costs. Do we perform preventive maintenance on this HVAC machine? Probably. But we have a few different levers to turn.

How often should we perform preventive maintenance? Should we do it every four months, six months, or eight months? This is something that’s a bit controversial and needs to be looked at from a cost perspective. At the end of the day, preventive maintenance can be expensive if you are over-maintaining something. But it can help prevent critical failures, so we need to make sure we are maintaining the right thing at the right frequency.

When to Schedule Preventive Maintenance

The two most common ways to schedule preventive maintenance are based on time

or usage.

In the first case, you’ll determine that a particular piece of equipment should be inspected, cleaned, or maintained every so many months or years. This is akin to changing the oil in your car every three months or your furnace filter every six months.

In the second case, you’ll schedule preventive maintenance based on usage. Heavily-used equipment should be serviced more frequently than under-used machinery. For example, you’d want to change the oil in your car every 3,000 miles even if you drove that distance in one month instead of three.

Usage is generally the best method. Obviously if you run consistently, then you can translate to time, but usage makes the most sense. Sometimes facilities change the operating conditions, but forget that their preventive maintenance schedules are based on time, and they experience failures because of it.

It’s also possible to over-maintain equipment, which might be a confusing concept. After all, the definition of maintain is to keep something running well, so how can something run too well?

However, some asset factors can actually be damaging to the asset if they are overdone. Take lubrication, for example. If a technician sees that a part is sufficiently lubricated but decides to add more grease because of the preventive maintenance schedule, the excess grease could actually damage other parts of the machine and cause a breakdown.

The Benefits of Preventive Maintenance

Ultimately, the primary benefits of preventive maintenance come down to reliability. As you keep each asset in good repair, it’s less likely to break down, and thus, you have less downtime over the life of the asset. Decreasing downtime or eliminating emergency production line breakdowns can often result in significant savings.

There are more benefits of implementing a preventive maintenance program than merely reducing the amount of unplanned downtime. Other benefits include:

Extension of asset lifetime

Increased safety and reduced risk of injury

Optimized maintenance planning and resource allocation

Less expensive corrective repairs

Better margins and profits due to less downtime

Perhaps the greatest benefit is increased safety, especially for a company that owns heavy machinery. The price of employee safety is never too high, and organizations such as OSHA rigorously enforce government policy.

How Can Preventive Maintenance Improve Workplace Safety?

We often tout preventive maintenance as a way to reduce expenses from unplanned downtime, but it’s true that preventive maintenance can improve safety as well.

How? It all comes down to the fact that when heavy equipment starts wearing out, it can get dangerous. To really understand the impact preventive maintenance has on workplace safety, it might help to look at a few examples.

Detecting Equipment Failure

Equipment failures can result from something as simple as a worn belt or a damaged roller. Depending on the situation, even a minor issue can become dangerous. For example, steel cobbles are wildly dangerous, and they can result from damaged rollers. A faulty cutoff valve on a boiler could result in massive injuries for those nearby.

If a piece of equipment fails while in operation, any nearby workers could be put at risk. Preventive maintenance serves to prevent those types of failures, thereby keeping operations crews safe.

Preventing Hazardous Situations

Some of the risks posed by poorly maintained equipment are less dramatic but still significant. For example, a poorly maintained ventilation system could lead to dangerous gas buildup. HVAC maintenance is key for most plants, and that requires regular preventive maintenance.

Another example would be leaks or condensation, leading to pooled water and posing a slip-and-fall hazard. These issues often result from poorly maintained assets, such as condensation from a malfunctioning freezer. Again, regular inspections would head off this problem.

Unplanned Downtime and LOTO

Unplanned downtime can in itself be hazardous. The reason for this is because in order to do work on a malfunctioning asset, you’d need to shut it down, and not everyone does that properly.

Lockout-tagout (LOTO) procedures are designed to make sure a broken asset is completely off and ready to work on. However, not everyone has proper LOTO procedures, and they might be ignored in a rushed production scenario. In fact, LOTO-related violations were one of the top 10 most frequent OSHA citations in 2018.

Incidentally, OSHA requires companies to have some kind of preventive maintenance program in place. Consistent inspections and preventive maintenance make sure assets don’t break down as often, eliminating the risk that LOTO procedures might be ignored. If repairs are needed, having a solid LOTO procedure in place will further minimize the risk of injury.

When Should I Start a Preventive Maintenance Program?

Ideally, you should try implementing a preventive maintenance program as soon as possible. You’ll want to start small, and you’ll need to have a few things going for you first. Preventive maintenance is an ongoing endeavor, so you need the resources in place to be able to handle it.

Before You Get Started

Before getting started with a preventive maintenance program, consider these questions:

Do you have enough staff on board to handle recurring maintenance checks and upkeep?

Are you capable of providing training to transition over to preventive maintenance processes and software?

Do you have the administrative processes in place to plan and schedule preventive maintenance tasks?

Do you have the expertise to define preventive maintenance tasks?

Do you have the budget/resources to take on the additional upfront costs of establishing a preventive maintenance program?

Are You Ready to Start a Preventive Maintenance Program?

If you answered no to any of the questions above, it may be best to take care of those items first before creating a full-blown preventive maintenance program. More growth may be necessary, or you may simply need to make adjustments to your maintenance management processes.

For example, if your maintenance manager doesn’t currently have time to plan out maintenance tasks, they may need to delegate some of their tasks to another staff member before a preventive maintenance program becomes feasible.

On the other hand, if you can answer yes to each of these questions, you’re ready to get started with a preventive maintenance program. Keep in mind that preventive maintenance may be simpler than you think. You’re probably performing some preventive maintenance tasks already, such as lubrication or cleaning. Creating a preventive maintenance program is simply structuring those tasks into an organized plan. It doesn’t have to be complicated, and it’s made even simpler with a CMMS to schedule tasks and track asset health.

As you start your preventive maintenance program, keep in mind that you don’t need to put every asset you own on your program. In fact, you probably shouldn’t plan preventive maintenance for everything. When starting out, you’ll want to make plans for one item at a time, adding assets as your capacity increases.

An Example of an Effective Preventive Maintenance Plan

"Preventive maintenance should be conducted as a controlled experiment, where we perform certain actions to meet a desired outcome. Also, insanity is performing preventive maintenance on equipment that continues to break down." -Ricky Smith, CMRP, CMRT, UpKeep Expert in Residence

Let’s take an example of a preventive maintenance program for heavy machinery. Such an asset may be one of the most expensive pieces of equipment your business owns, and it can also be expensive to fix. In our example, this asset plays a critical role in the operation of your company on a daily basis.

If this machine costs $100,000 new and requires $30,000 in maintenance and repair over 7,000 hours of operation, we can reduce those costs effectively with a preventive maintenance program. In some cases, preventive maintenance may reduce overall maintenance costs by one quarter. Here’s a step-by-step plan for putting a preventive maintenance program in place.

A Step-by-Step Approach to Implementing Preventive Maintenance

Before you implement a preventive maintenance plan, be sure you have a good understanding of which assets and processes will benefit most. According to IBM, as much as 50 percent of the money you spend creating a preventive maintenance plan can be wasted.

This is primarily because companies are focusing on maintenance tasks that do not prevent failure. It’s important to begin by identifying critical assets that have particular failure modes, which can be prevented by a good preventive maintenance plan. Simply checking all equipment and performing maintenance tasks alone will not necessarily improve reliability or performance.

Commit as a company to a preventive maintenance program. That means you need buy-in from both your top management and your maintenance technicians. Be sure you have the necessary tools and processes in place as well as an individual accountable for the preventive maintenance program.

Establish a preventive maintenance checklist for your critical equipment. This can be based upon manufacturer recommendations or technician experience.

Find the major reasons that your critical asset breaks down. By identifying the likely causes of failure, you can build a preventive maintenance program that is directly tied to reducing the chances of that failure. Equipment may break down suddenly with a very obvious cause, intermittently with a less obvious cause, or gradually, as wear and tear decreases the efficiency of the assets. Many failures can be linked to temperature issues or mechanical problems.

Become familiar with your assets. If you’re dealing with a brand-new machine, be sure to invest the time in reading the manual and getting to know your equipment as best as possible. Once it’s put into operation, be sure to tap the knowledge of

the operators and technicians that work with the piece of equipment. They will begin gathering a great deal of knowledge about how the asset operates and what type of maintenance tasks seem to be most helpful. Use a CMMS to help document all this information for easy access in the future.Incorporate an aspect of continuous improvement and ongoing training in your preventive maintenance program. Employees must understand how to effectively use their equipment as well as ways to care for their machinery. In addition, if operators are trained as valuable members of a business, they will be more likely to keep an eye out for suspicious equipment activity and sound an early warning.

Start with the manufacturer-recommended maintenance schedule. Remember that the producers of heavy equipment tend to spend a great deal of time testing their machinery before customers use it. This can be an excellent starting point to establish a preventive maintenance program. However, you’ll want to take into consideration special circumstances such as how your organization is using the equipment, as well as local weather and specific site conditions. A great deal of mud, snow, humidity, and heat may shorten the time required between preventive maintenance activities.

Keep track of all information and any changes. As time goes on, you’ll be able

to accumulate a great deal of information starting with manufacturer manuals and instructions. However, you’ll also be able to see what type of maintenance tasks and repairs have been performed over time. The quality of this information will help the management team make smart decisions in terms of future maintenance activities as well as repair and replace decisions down the road.

How to Create a Preventive Maintenance Checklist

Preventive maintenance checklists outline the tasks maintenance personnel need to perform when examining or repairing equipment. Well-designed checklists help reduce human error, improve reliability, and much more. To create the ultimate preventive maintenance checklist, follow these steps:

Outline your maintenance goals

Audit your equipment

Note any applicable standards and regulations

Select assets

Outline preventive maintenance tasks for each asset

Create checklist items

Train your personnel

Track the results and adjust

To be successful, preventive maintenance checklists also need to be thorough. The components of your checklists should include the following.

Asset/System Being Checked

Naturally, the first on the list should be the item or system being checked. Having each list clearly labeled for specific assets will help keep processes organized.

Required Equipment

Each checklist should have a list of required tools and equipment, including PPE (personal protective equipment), lubricant, and replacement parts. Having these items clearly detailed on the list will make sure your technicians have everything they need while out on the floor, preventing any back-and-forth trips to get extra parts or tools.

Tasks to Complete

Next is the list of tasks to be completed. These should be as detailed as they need to be but still concise.

On some checklists, the items listed may be step-by-step tasks performed by a maintenance technician. An example might be a routine checkup on a mixer that requires the technician to first lock down the equipment, then check for/clean out any buildup, and so on.

Other checklists may be formatted as a “pass/fail” list, where the technician or operator checks various items to see if they meet the requirements outlined under each item. Any items marked as “fail” would trigger a

work order.

Responses

Each item on your checklist should have space for responses. Some of the common types of responses on maintenance checklists include:

Open, In Progress, On Hold, Complete

Pass, Fail, Flag

Multiple-choice items

Descriptions and notes

The types of responses you choose will depend on the asset being serviced and the purpose of the checklist. For instance, an inspection checklist would use a pass/fail format, whereas a routine lubrication task might use open/in progress/complete.

Time to Complete

It’s best practice to include the time the checklist should take to complete. Doing so helps keep maintenance technicians on task, while at the same time, pushes them to complete each item properly (as opposed to just pencil whipping the whole procedure).

Including the anticipated hours required for each checklist will also help your maintenance planner and supervisors when it comes to planning and assigning tasks for each workday.

Frequency

The frequency for each task should be specified. In some cases, you may have separate lists or sections for weekly, monthly, and yearly tasks. Otherwise, the items on the list should list their own specific time interval in order to make sure they’re done as often as needed.

Additional Details

Maintenance checklists may include other details on top of those described above, including:

Pictures of the equipment and individual parts

The date and time (for completed checklists)

Follow-up actions triggered by items on the checklist, such as creating work orders

Safety warnings wherever applicable

By following these steps and best practices, you’ll be able to create the ultimate preventive maintenance checklist for your facility. When done properly, your preventive maintenance checklist will help improve safety, efficiency, and reliability in your facility.

Things to Watch Out for With Preventive Maintenance

Planning

Much like the actual maintenance tasks themselves, setting up a preventive maintenance program requires some intense planning. This answer might actually surprise some people because a CMMS makes it seem so easy. While a CMMS does help with scheduling and assigning work, it’s not a cure-all; it’s a tool that complements a solid preventive maintenance plan.

Prior to implementation, organizations need to plan out:

The purpose and goals of the preventive maintenance program

Necessary documentation for preventive maintenance procedures

Measuring minimum performance metrics for assets

Setting Unclear Instructions

Preventive maintenance programs can be complex, and many organizations can make these common mistakes that can cost both time and money. One of the most common mistakes is to provide unclear and vague instructions. Be sure to create step-by-step instructions with specific measurements and tasks to complete.

Remember that directions such as "check this" or "inspect that" mean very different things to different technicians. Unclear instructions can lead maintenance technicians to record a preventive maintenance task as completed without actually finishing the work. Instead, make instructions specific, such as "check that the temperature is at or below 0 degrees F".

Schedule Compliance

This is a tough one because it’s difficult to measure how well or poorly a facility is complying with a schedule. Ultimately, though, if preventive maintenance tasks aren’t being performed, there’s something wrong.

Schedule compliance is a multi-factored issue, so there are a few things you can try to increase adherence to maintenance intervals:

Make sure technicians aren't swamped with too much work to handle.

Check for necessary training and qualifications in technicians.

Gather employee feedback to check the viability of the schedule.

Not Outlining Feasible Timeframes

Although having a short window of opportunity where preventive maintenance tasks should be performed is a good idea, it’s important to realize that performing them too early or too late both generate problems. If a piece of equipment is over-maintained, a company can be wasting precious labor and money resources. In many cases, maintenance tasks that are performed too frequently do nothing to prevent failure and are essentially a waste of time and resources.

Errors in Prioritization

Before implementing a preventive maintenance program, it’s important to prioritize the assets and activities that have the highest chance of preventing failure. By tying preventive maintenance programs to those pieces of equipment that play an important role in keeping your production lines moving or ensuring the safety of your employees, you will reap the most benefits from your preventive maintenance program.

Mishaps in MRO Parts

It’s important that you have a solid MRO inventory on hand, which will allow your maintenance technicians to have all the tools, testing equipment, or other resources needed to perform their jobs quickly and efficiently. Starting a work order only to discover that you’re missing key tools is not only frustrating but also very inefficient.

Forgetting to Document All Completed Work

Finally, it’s most important to track your preventive maintenance program, so that improvements can be made and problems can be identified. A CMMS can help you do just that, providing detailed analysis and reports to help your management team make better business decisions.

How to Get Team Buy-In

If you want a successful preventive maintenance program, you have to start with the technicians and operators. They are the ones implementing the day-to-day program, and if they don’t buy into it, failure is imminent. In fact, it’s been said that between 80 to 90 percent of all CMMS implementations fail. One big component of that is the lack of acceptance by the maintenance team. Take a look at the following practical ways to help get your frontline technicians, as well as the rest of your organization, behind a preventive maintenance program to ensure its success.

Explain What's in It for Them

It’s easy to understand the skepticism that sometimes abounds within business. To the frontline employees, it can seem like management rolls out a new program every few months. If programs have fallen by the wayside in the past, your technicians may view a new preventive maintenance initiative as more corporate-speak and keep doing the things they’ve been doing.

Instead of simply introducing preventive maintenance as an abstract concept designed to improve efficiency and cut costs, put the benefits in terms of what’s in it for the technicians. For example:

Tie reaching preventive maintenance benchmarks to technician bonuses.

Introduce promotion opportunities made available by preventive maintenance technology.

Solicit feedback about preventive maintenance tasks and processes.

If technicians understand why they should do something differently, they will have some skin in the game and be much more likely to follow through with requirements.

Collect the Data

This all starts with collecting data. It’s not enough to tell your operations department that a little bit of planned downtime now will be beneficial overall. You need to show how it will maximize uptime in the long run.

To do that, you’ll need to look at the following metrics:

Mean time between failures on key assets

Mean time to repair those assets when they fail

Unplanned equipment downtime

Average completion time for preventive maintenance work orders

Root cause analysis to show how certain preventive maintenance tasks can prevent costly failures

Use these metrics to demonstrate the time lost on unplanned maintenance and compare that to the time it takes to complete preventive maintenance tasks. Doing so, you should make your case for how a little planned downtime can support equipment uptime. In the end, the cost savings on preventive maintenance tend to come out to between 12% to 18% over reactive maintenance, so the numbers should work out in favor of preventive maintenance.

Communicate and Collaborate

These statistics can ultimately help you align your purposes. After all, the end goal of both maintenance and operations is to support production and profitability. Maintenance and operations leadership should be working together to that end. As such, communication and collaboration are key.

For instance, maintenance planners should maintain consistent communication with the operations department. As maintenance planners schedule work, they should collaborate with the operations department to make sure the equipment is clean and ready for planned tasks.

Scheduling regular meetings between the two departments can also help. The focus of these meetings should be on determining the root causes and solving them (and not on pointing fingers).

Conclusion

The bottom line is that a preventive maintenance program can be an excellent way to help a company reduce breakdowns, minimize downtime, improve efficiency, and lengthen equipment lifespan. However, like with any program, it’s important to understand what types of situations and what kind of equipment can benefit the most from a solid preventive maintenance program.

Be sure to identify those critical assets that play an important role in the daily operation of your company or are critical to employee safety or environmental compliance. In addition, you’ll

want to identify potential sources of failures for those pieces of equipment, so that a preventive maintenance program can be directly tied to improving reliability.

Once that foundation has been set, be sure you have the tools, processes, and people in place in order to execute the program successfully. Clear and complete instructions, as well as technician training, will be critical to the effectiveness of a preventive maintenance program. Finally, be sure to have a way to track all the tasks, checklists, and history on an ongoing basis. If high-quality data is collected throughout the process, the management team will have an excellent resource to analyze critical equipment performance and make smarter business decisions in the long run.

Want to keep reading?

Maintenance

Cultivating Maintenance Excellence: The Role of Culture and Leadership in Reliability

Maintenance

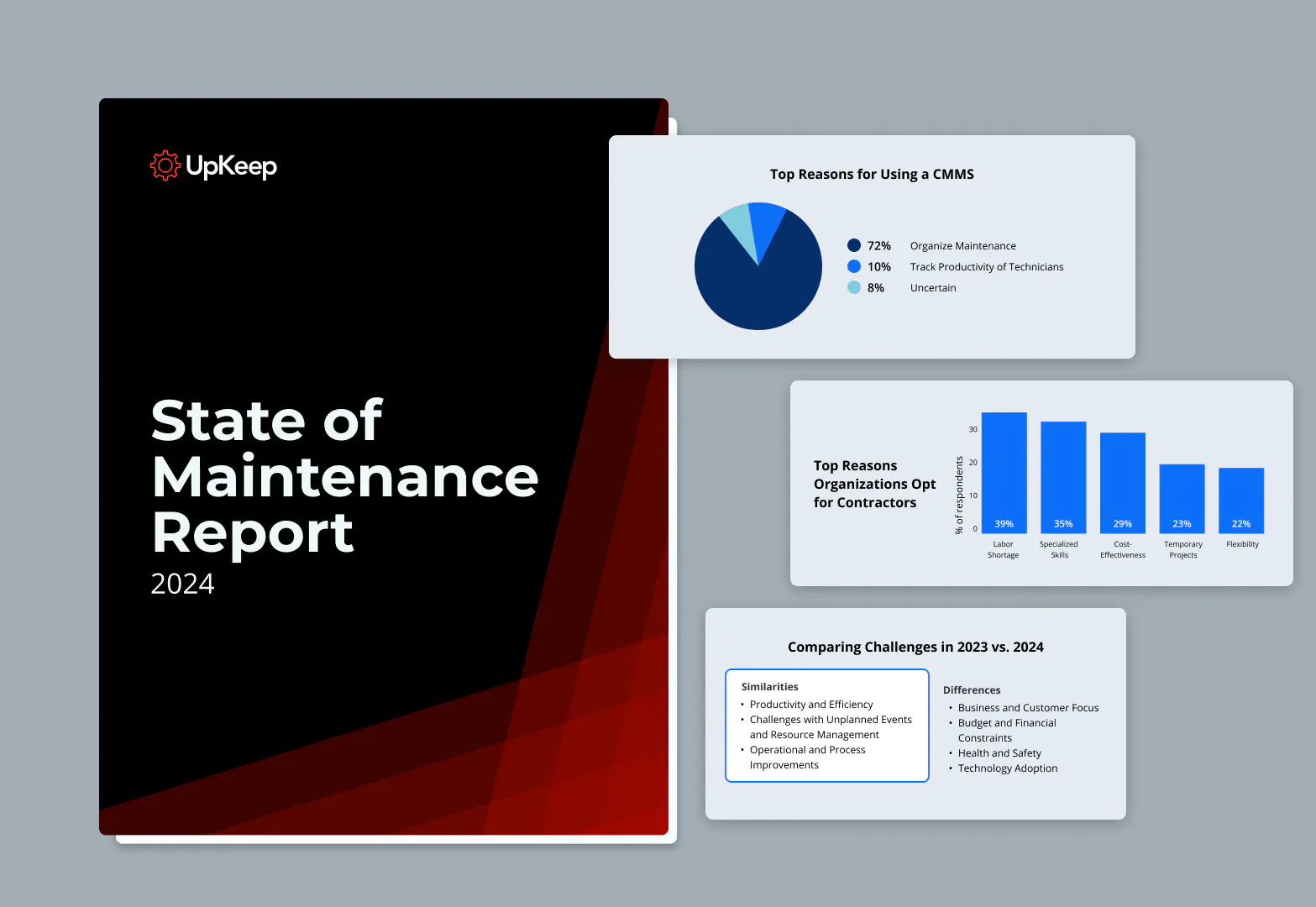

State of Maintenance Report 2024

Maintenance

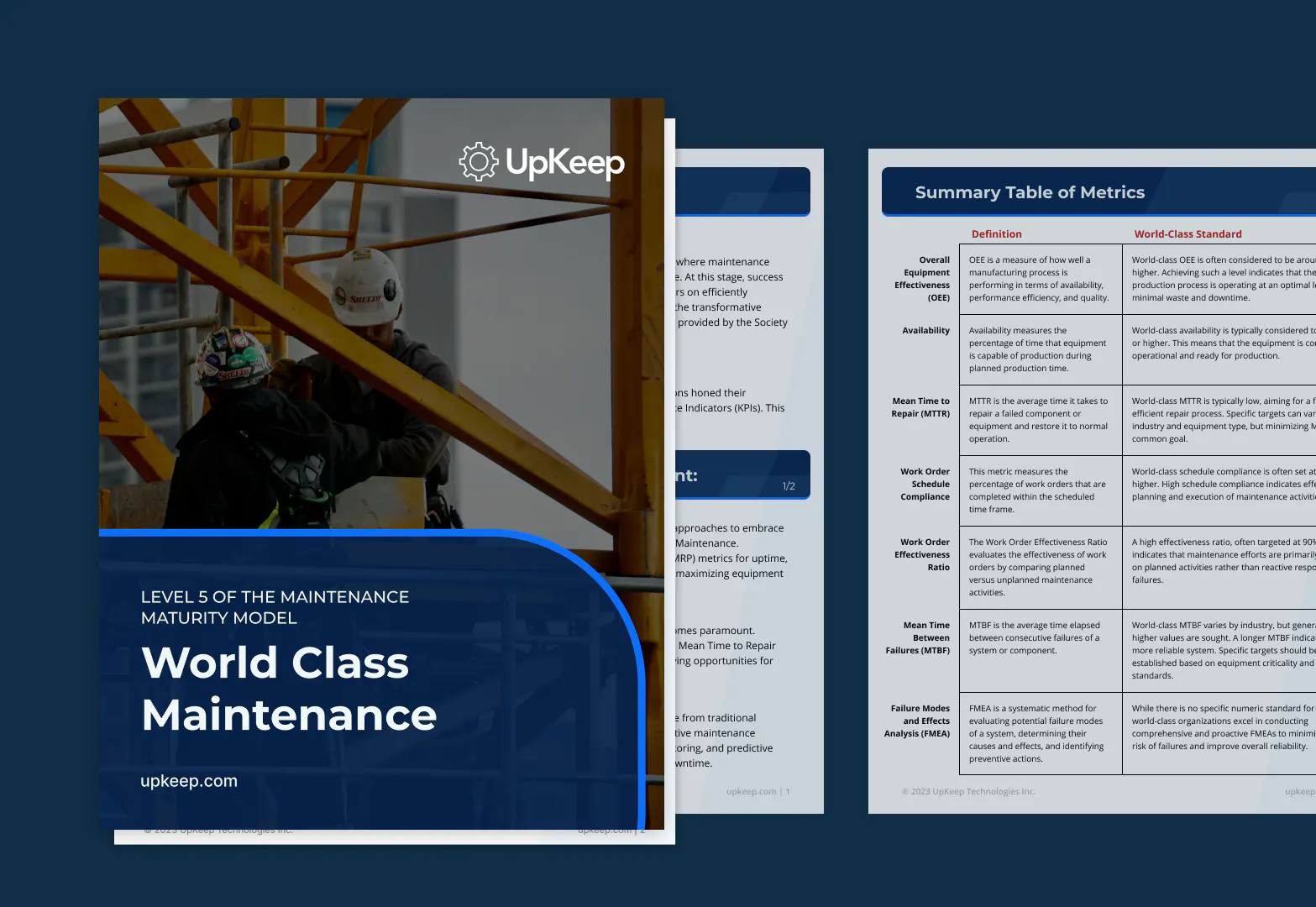

World Class Maintenance: Level 5 of the Maintenance Maturity Model

4,000+ Companies Rely on UpKeep's Asset Operations Management Software