An equipment maintenance log is a document that records activities that have been performed on an asset.

It takes at least a handful of key equipment to keep a plant operational. It is unimaginable how much time and effort goes into maintenance activities for each asset annually. Compounded by the total number of equipment and combined years of operation, documentation of maintenance tasks can easily get out of hand without a systematic process for tracking activities.

3 types of maintenance logs

1. Maintenance schedule logs

Maintenance schedule logs are a timetable for all the projects in progress within an organization. These logs provide a holistic overview of everything the company is working on at any given time, as well as an expected timeline for completion.

2. Machinery maintenance logs

Machinery maintenance logs contain information about scheduled maintenance for all of the machines used by the organization. These logs ensure that teams service their machinery within the specified interval to keep it operating efficiently.

3. Project logs

Project logs track the company’s current projects. Similar to maintenance schedule logs, they help organizations look at ongoing work and expected completion timelines. Project logs may include maintenance schedule logs, as well as projects from other departments. They also cover completed projects.

Maintenance activities are invaluable in maximizing an asset’s life span. To help make sure that maintenance tasks are done diligently, records in the form of maintenance logs need to be created and updated.

By keeping maintenance activities well-documented, the whole organization is kept up to speed on the status of an asset. Being aware of the current condition of the assets is a step towards improving the overall plant performance and ensuring safe working conditions.

Benefits of using equipment maintenance logs

Companies use equipment maintenance logs to monitor the conditions of their equipment. Their business operations depend on the functionality of their assets, so it is important to have high-quality equipment maintenance logs. The benefits of keeping good logs include creating more cost-effective decisions, increasing the resale value of equipment, and developing specialized equipment maintenance programs.

Creates more cost-effective decisions

Having clear records of completed tasks can enable maintenance planners to more easily plan out future activities and more efficiently delegate resources. More cost-effective decisions can be made given a clear picture of the status of equipment maintenance activities.

Increase equipment resale value

Keeping maintenance logs updated is proof that assets are being taken care of. In the event that facilities need to be upgraded and existing assets need to be sold, detailed maintenance logs can help increase the resale value of the equipment.

Develop specialized equipment maintenance programs

Equipment maintenance logs provide rich historical data that can be analyzed to provide insights on an asset’s performance compared to similar devices. Different equipment makes or models, for example, can be compared by analyzing differences in maintenance costs incurred, frequencies of unplanned maintenance activities, etc.

With available technologies, the benefits of having a well-documented equipment maintenance log are more easily achieved than ever.

Equipment maintenance log template

An equipment maintenance log may vary for each company. The general idea is that each piece of equipment has its own maintenance log and each maintenance log has spaces to be filled in with details each time a maintenance activity is performed.

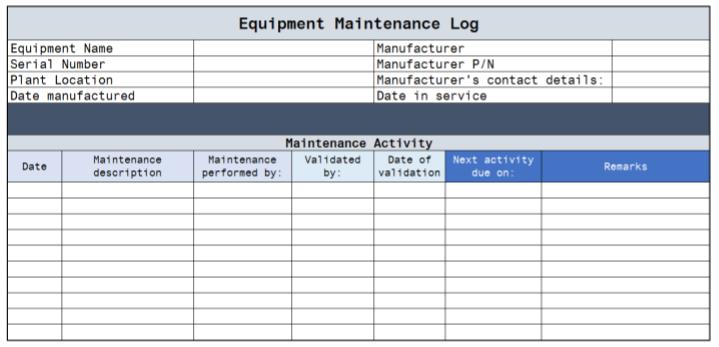

A sample template, if printed out on paper, might resemble the following...

Notice that the header provides information about the equipment: equipment name, serial number, plant location, manufacturer, manufacturer part number, manufacturer contact details, date manufactured, and date in service.

Each log will be kept separate even for similar types of equipment. For example, two same-sized centrifugal pumps from the same manufacturer will differ in the serial number and/or plant location. Keeping separate logs for each pump ensures that there is no confusion about which maintenance log refers to which piece of equipment.

The second part allows entries of maintenance activities. Details about the maintenance activity are listed: the date when it was performed, and a description of the activity and the person who performed the activity. The person is responsible for validating that the maintenance procedures were performed correctly is also included. The next scheduled date for any required action and other remarks can also be added for reference.

Tips for updating an equipment maintenance log template

From the previous example, updating maintenance logs seems like a tedious process that requires stacks of paperwork each time maintenance operations take place. However, you might notice that the information in a typical maintenance log would already be available in a work order that each servicing task would usually come with.

CMMS software would eliminate most of the manual processes of accomplishing maintenance logs by automatically updating them as work orders in the system are closed. This enables the maintenance teams to more accurately track historical accounts of maintenance activity.

Updating equipment maintenance logs used to be a manual process of filling in each of the fields on a form such as an example shown above. This would have to be done each time any maintenance work was performed for any of the key assets in the plant. Though antiquated, some maintenance and asset management teams still use manual pen-and-paper methods for updating equipment maintenance logs.

![[Review Badge] GetApp CMMS 2022 (Dark)](https://www.datocms-assets.com/38028/1673900459-get-app-logo-dark.png?auto=compress&fm=webp&w=347)

![[Review Badge] Gartner Peer Insights (Dark)](https://www.datocms-assets.com/38028/1673900494-gartner-logo-dark.png?auto=compress&fm=webp&w=336)