What is it?

Breakdown maintenance is maintenance performed on a piece of equipment that has broken down, faulted, or otherwise cannot be operated. The goal of breakdown-maintenance is to fix something that has malfunctioned. To the contrary, preventive maintenance is performed in order to keep something running.

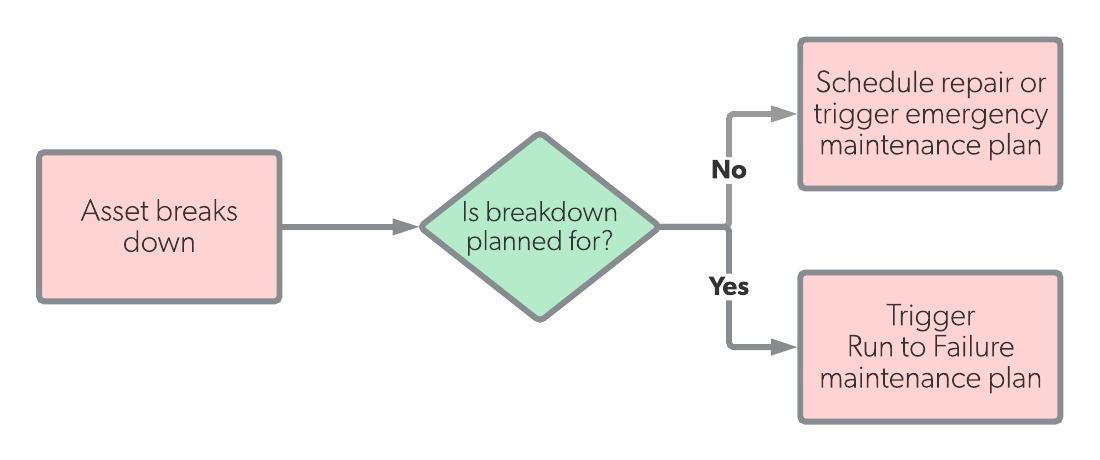

Sometimes it is performed because of an unplanned event. For example, if a critical piece of machinery breaks, the maintenance is performed because of the imminent need for that machine to operate again. However, breakdown-maintenance can be planned for in advance, which is what we might call “good” breakdown-maintenance.

Breakdown Maintenance Workflow

2 types of breakdown maintenance

There are two types:

Planned maintenance

Planned maintenance means that the organization is prepared for a breakdown and even expects it to happen. The equipment runs until it breaks, which initiates a run to failure (RTF) trigger. While RTF triggers can be unplanned, breakdown-maintenance plans use RTF as a way of lowering the cost of maintenance.

This kind of plan needs to be rigorously documented and controlled. Employees should be clear on exactly which parts will break down and which parts will be maintained normally via preventive maintenance. Without these checks, a breakdown maintenance plan can be exploited or run awry.

Unplanned breakdown maintenance

Unplanned breakdown maintenance, on the other hand, occurs when a piece of equipment fails or breaks unexpectedly—also called an unplanned downtime event. While some facilities may not utilize a planned maintenance plan, nearly every facility needs resources in place for unplanned maintenance. After all, every piece of equipment will break or fault at some point in its life.

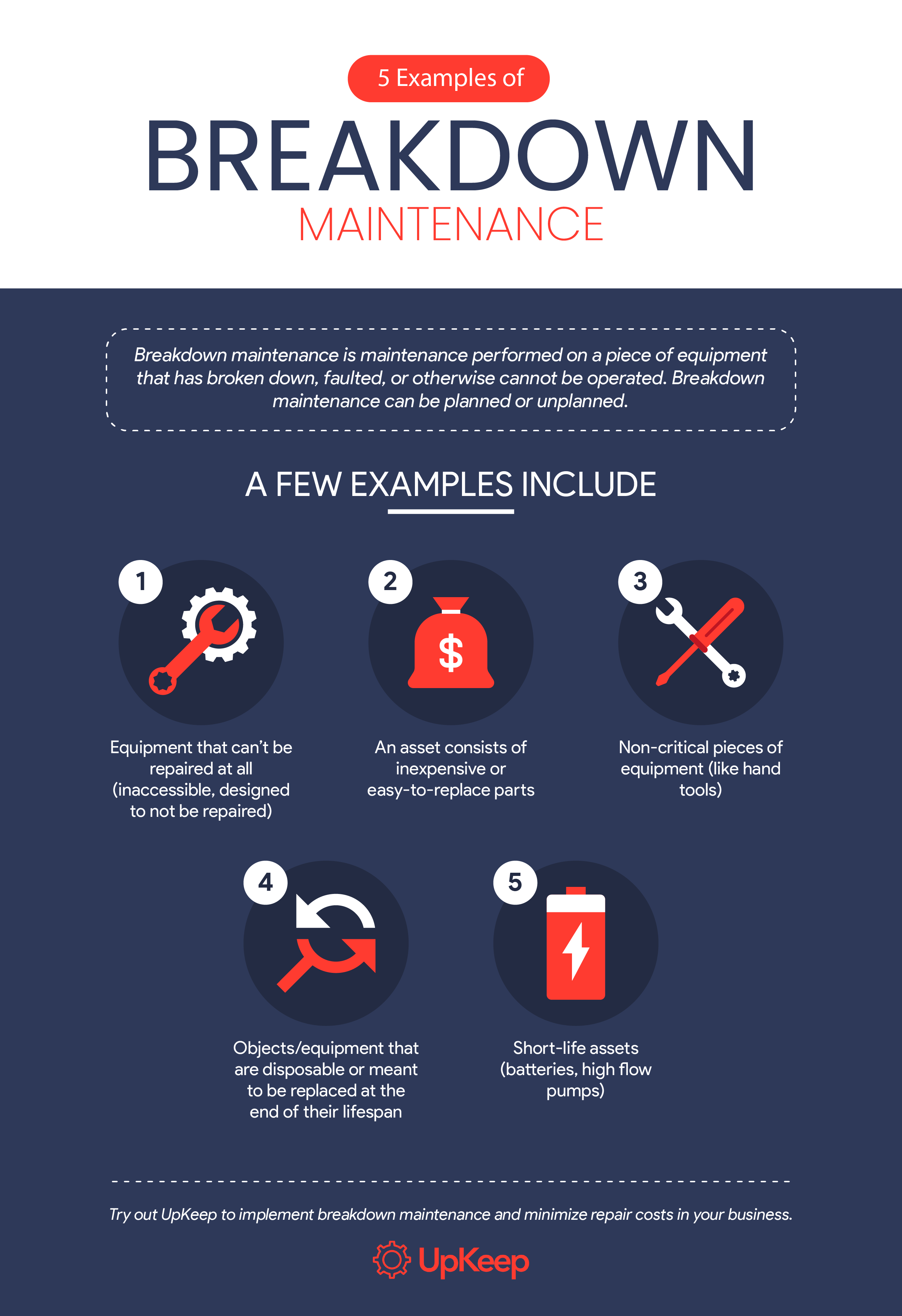

5 examples of breakdown maintenance

It is unique in its applications because it cannot be used with certain industries or products, especially ones that involve health and safety. This means that it is most frequently used when parts are inexpensive or nonessential.

Here are some examples in which breakdown maintenance is applicable:

- Equipment can’t be repaired at all (inaccessible, designed to not be repaired)

- Asset consists of inexpensive or easy-to-replace parts

- Non-critical pieces of equipment (like hand tools)

- Objects/equipment that are disposable or meant to be replaced at the end of their lifespan

- Short-life assets (batteries, high flow pumps)

As you can see from these examples, it becomes viable when there’s no inherent safety risk to letting a part or piece of equipment break. As an example, consider a facility’s light bulbs. If a light bulb is not linked to a safety feature, it doesn’t make financial sense to replace it before it has burned out.

However, it is absolutely not viable when people’s lives can be endangered by a part or product breaking. For example, the aviation industry cannot rely on parts breaking down to fix them because doing so could threaten the personal wellbeing and safety of people on planes. This is also true for tire manufacturers who are responsible for road safety. When it comes to people’s lives, preventive and predictive maintenance are the right choice.

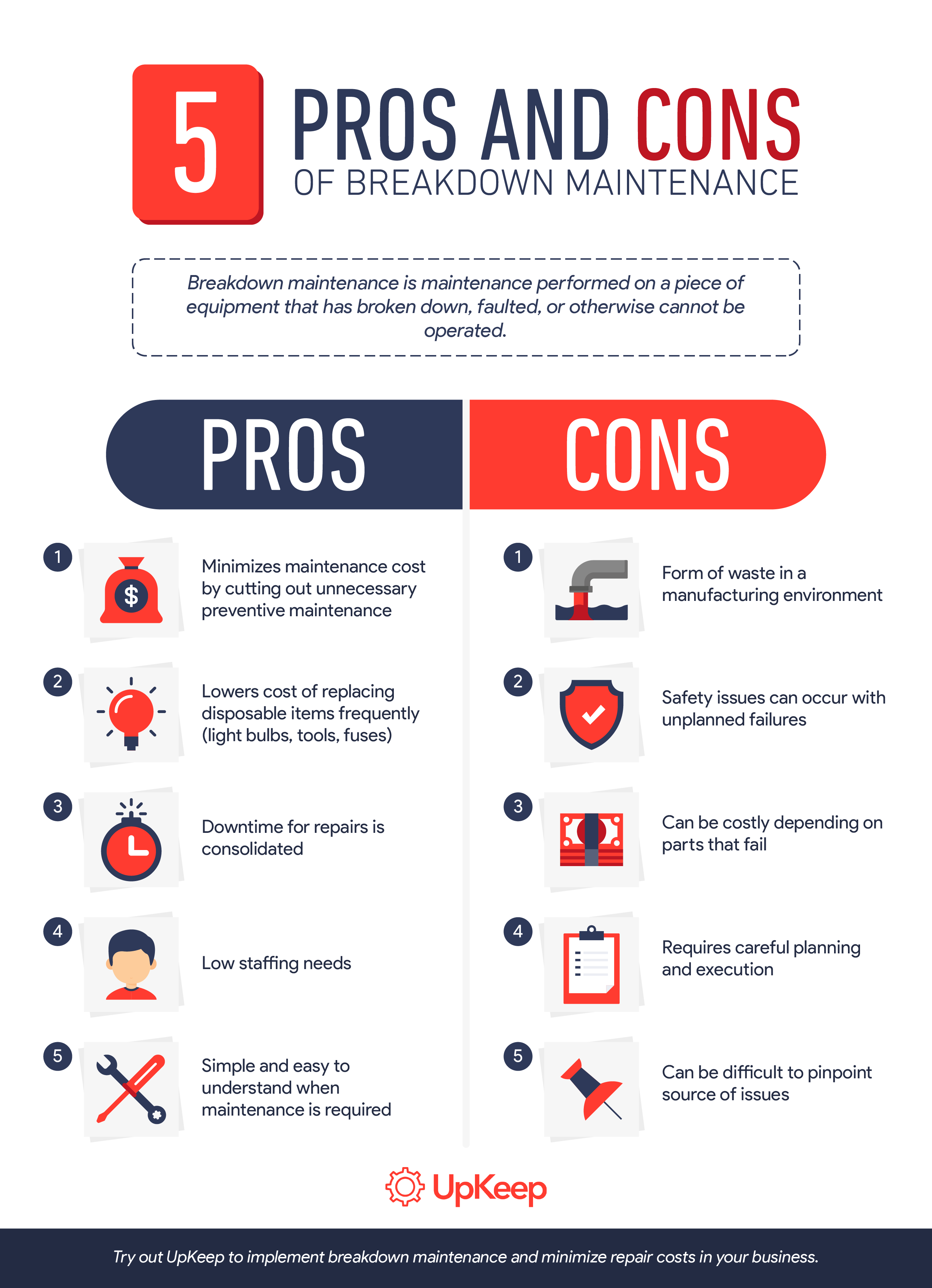

Pros and cons

Pros

Failed equipment can lead to disastrous consequences, but a clearly-documented maintenance plan can actually have a few significant benefits for an organization.

- Minimizes maintenance cost by cutting out unnecessary preventive maintenance

- Lowers cost of replacing disposable items frequently (light bulbs, tools, fuses)

- Downtime for repairs is consolidated

- Low staffing needs

- Simple and easy to understand when maintenance is required

Cons

The downsides of breakdown-maintenance are especially important to weigh given the nature of the maintenance plan. For example, breakdown-maintenance should never be used with safety equipment because a single lapse can cost one or multiple employees their health or their lives.

- Form of waste in a manufacturing environment

- Safety issues can occur with unplanned failures

- Can be costly depending on parts that fail

- Requires careful planning and execution

- Can be difficult to pinpoint source of issues

Breakdown vs. corrective maintenance

Some may wonder what the difference is between breakdown and corrective maintenance. Both work with equipment that is faulty, less than optimized, and/or broken. However, the two terms are not necessarily the same thing.

Breakdown maintenance, as you just learned, is performed on equipment that is broken, faulted, or otherwise stopped in such a manner as to make the equipment nonoperational. Corrective maintenance is focused on rectifying and repairing faulty equipment.

On the surface, the two look very similar. Let's dive into the major differences to clear up any confusion.

How the two maintenance types differ

The biggest difference is that breakdown maintenance works on equipment that is nonoperational. Corrective maintenance takes place on equipment that is still functioning to some extent but will not function at optimal capacity without the maintenance being performed.

Corrective maintenance may very well be applied as a machine or equipment in question is still working. Breakdown maintenance may happen in an extremely short period of time, particularly if the system in question is essential.

Both types of maintenance typically happen to equipment that is still in its place or on the line. Also, both types of maintenance may be classified as emergency maintenance, depending on the situation.

![[Review Badge] GetApp CMMS 2022 (Dark)](https://www.datocms-assets.com/38028/1673900459-get-app-logo-dark.png?auto=compress&fm=webp&w=347)

![[Review Badge] Gartner Peer Insights (Dark)](https://www.datocms-assets.com/38028/1673900494-gartner-logo-dark.png?auto=compress&fm=webp&w=336)