Corrective maintenance is the category of maintenance tasks that are performed to rectify and repair faulty systems and equipment. The purpose of corrective maintenance is to restore systems that have broken down. Corrective maintenance can be synonymous with breakdown or reactive maintenance.

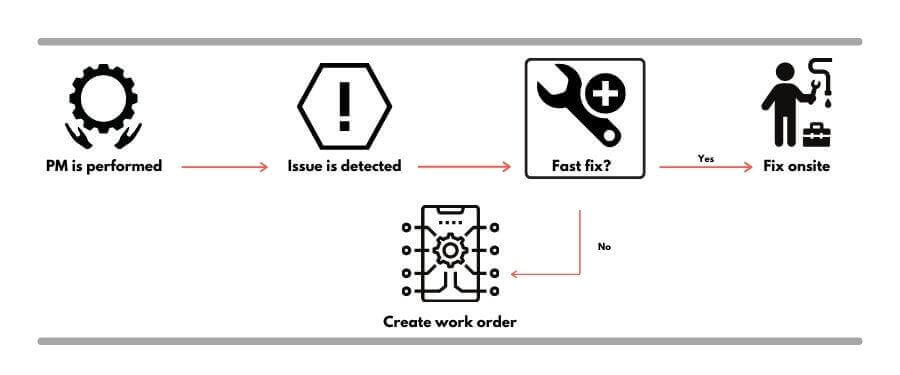

Corrective Maintenance Workflow

How Are Corrective Maintenance Needs Identified?

Corrective maintenance orders are typically initiated when an additional problem is discovered during a separate work order. For example, if a maintenance technician spots an issue during an emergency repair, as part of a routine inspection or in the process of conducting preventive maintenance, that issue can turn into a corrective maintenance order. That corrective maintenance task is then planned and scheduled for a future time. During the execution of corrective maintenance work, the asset is repaired, restored, or replaced as needed.

Examples of Corrective Maintenance

Corrective maintenance may be performed on a wide variety of equipment, systems, and processes. Here are a few examples:

- Production line. A technician is performing preventive maintenance on a line of production equipment and notices significant wear on a critical part or component. A corrective maintenance order can be initiated to repair or restore that part within the next month.

- HVAC systems. A technician responds to an emergency heating system repair in the middle of winter and notices partially clogged or dirty filters. This can trigger a corrective maintenance request to clean or replace filters in the near future to improve efficiency and prevent further heat loss.

- Public works. While performing routine roadway repairs, a technician may notice some signage damage from a recent storm. A corrective maintenance order to restore that signage can be entered so the work is performed at a later date.

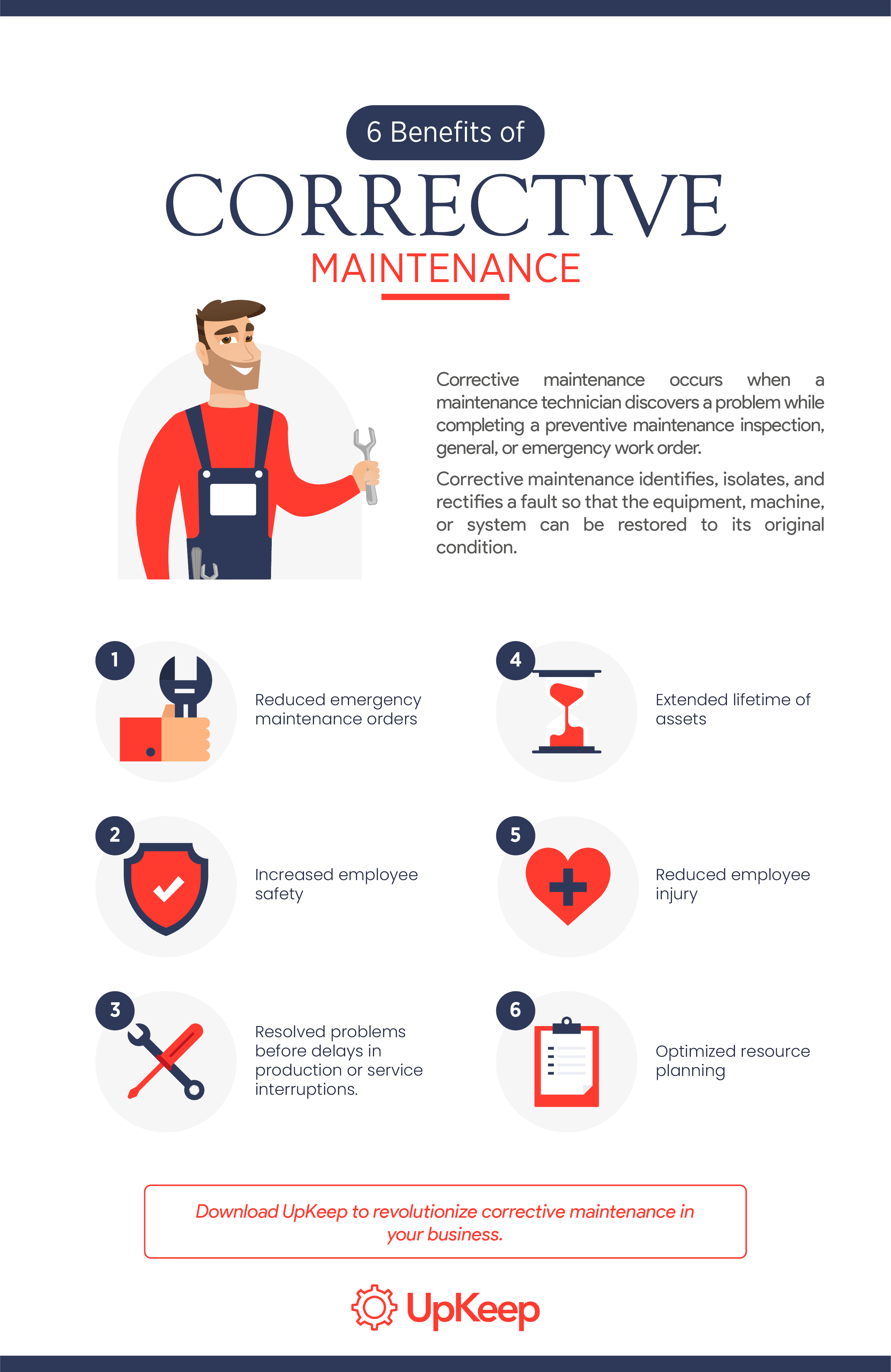

Benefits of Corrective Maintenance

Since the focus of corrective maintenance is to restore an asset so it can be functioning properly and efficiently, there are many benefits realized. Here are the largest benefits:

- Reduce emergency maintenance orders. If corrective orders can be executed in a timely manner once they are initiated, it’s likely that a company can reduce the number of emergency maintenance orders it generates. In general, corrective maintenance is less expensive than emergency maintenance.

- Increase employee safety. In some cases, the issues identified and tagged as corrective maintenance may have significant safety repercussions for employees working nearby the asset in question.

- Reduce service interruptions. Since corrective maintenance work orders are scheduled and prioritized in a computerized maintenance management system (CMMS), they can help maintenance teams resolve problems before delays in production or service interruptions occur.

- Extend asset lifetime. Corrective maintenance, coupled with good preventive maintenance, helps a business extend the lifetime of its assets. By noting corrective maintenance needs before they affect other components of the machine, companies can preserve the lifespan of critical assets.

- Optimize resource planning. Since corrective maintenance requests are sent back to a centralized system, they can be reviewed, prioritized, and scheduled appropriately. This allows both monetary and labor resources to be optimized throughout the organization.

- Decreases downtime. In some cases, corrective maintenance may help companies decrease downtime. For example, if a maintenance technician is performing routine maintenance on a piece of equipment and sees that a part is worn down, a corrective maintenance order can be placed immediately. Ideally, that task gets scheduled and completed before breakage or downtime occurs.

Maximizing Corrective Maintenance

Corrective maintenance has an important role within the scope of maintenance services in a business, residential complex, or factory setting. Technicians who can find and identify potential problems before they become emergencies can save the company a great deal of money.

To maximize the benefits of corrective maintenance, companies need to provide training and education to maintenance technicians and supervisors about what types of things to look for while they are providing preventive or emergency maintenance services.

Organizations may also want to create a maintenance checklist of components that technicians can visually check quickly. You want your maintenance staff to catch as many problems as possible, as early as possible. A checklist can help you generate more corrective maintenance orders, helping to keep your facility running smoothly in the long run.

How Corrective Maintenance Improves Reliability

Although corrective maintenance tasks are focused on restoring a piece of equipment to optimal functionality, it’s important not to let the opportunity go by to perform an additional quick inspection during the corrective maintenance task itself. In doing so, corrective maintenance provides an excellent opportunity to boost reliability.

Some assets in a facility will be monitored on a condition-basis and not necessarily maintained on a particular time-based schedule. If a corrective maintenance order is issued as a result of a failure mode trigger, it’s important to take the opportunity to inspect potential root causes for the failure in the first place. When a maintenance team takes advantage of the opportunity and identifies other issues to be addressed, it’s less likely that the failure will occur again or as frequently, boosting overall reliability.

One example is when the packing in a process pump fails. This typically occurs after a certain amount of usage and is not based on time. Therefore, anytime a technician is called in to repack a pump, a checklist of simple inspections should be made. These tasks may include things like checking wear and tear on the throat bushing, inspecting the shaft run-out, or looking at the water pressure. When a corrective maintenance request is initiated for a process pump repacking, these inspections should occur to identify other corrective maintenance needs.

By integrating inspections that are tied to failures such as these, a company can optimize its corrective maintenance process, as well as overall plant reliability.

Advantages and Disadvantages of Corrective Maintenance

Like any maintenance program, corrective maintenance has its advantages and disadvantages. It’s important to consider the pros and cons when implementing corrective maintenance in order to optimize your overall production and efficiency.

Most businesses typically try to shift from corrective or reactive maintenance programs to more preventive-based programs. Today, many companies are even moving further down the spectrum to predictive maintenance initiatives. Obviously, there are many advantages to being able to put systems in place that can detect problems before they occur. However, unexpected failures will continue to occur even with the best efforts. Corrective maintenance allows you to make the most of those inevitable opportunities.

The Plus Side of Corrective Maintenance

Since corrective maintenance is focused on repairing or restoring an asset when it fails, it requires very little in terms of labor, cost, and planning to implement. When the failure of a particular component has very little impact on safety, production, or service, it may be the best, most cost-effective solution. For example, implementing a complicated, expensive preventive maintenance plan to monitor something like a lightbulb replacement in the break room would not be prudent.

Here are some advantages of corrective maintenance:

- Lower costs. In the short term, corrective maintenance can be less expensive in some cases because you take care of the problem when it occurs. There is no labor required to track, monitor, and manage the situation.

- Simple process. Since corrective maintenance is reactive by nature, it can be a simple fix that requires very little planning or management.

- Inspection opportunity. Completing a corrective maintenance task also provides an opportunity to check out a piece of equipment due to a failure mode, and potentially, before a big interruption occurs.

The Minus Side of Corrective Maintenance

In cases where a failure can significantly affect production, employee safety, or environmental impact, solely relying on corrective maintenance can result in expensive and dangerous long-term problems.

Some disadvantages with an overreliance on corrective maintenance include:

- Unpredictability. If you only fix equipment when it breaks, running that asset will be very unpredictable in the long-run. In addition, root causes of the problems are typically not identified and therefore cannot be resolved efficiently.

- Interruption to production. If a critical piece of equipment breaks, it can stop your entire production line, leading to downtime and unproductive employees.

- Shortened asset lifespan. By not taking care of equipment and only performing maintenance when components break, you are shortening the overall lifespan of your assets.

How to Reduce Corrective Maintenance

Since corrective maintenance is often synonymous with reactive maintenance, it makes sense that organizations would be looking for ways to reduce the number of corrective maintenance orders. Although there are certain situations where it makes sense to simply correct a problem when it occurs, in many other cases, it’s better to prevent the problem in the first place.

Here are some ideas on how to reduce corrective maintenance orders at your company:

- Invest in the right technology. By implementing a CMMS solution, you can give your maintenance staff the ability to track and access critical data. These solutions can often generate analytics and reports that can help you make better decisions and prioritize the most critical work orders to maximize production and efficiency.

- Invest in your team. Refine your hiring process as well as your professional development program. Make sure you provide incentives for continuing education, additional certifications, or networking opportunities, so your team stays on top of the latest developments in the field.

- Train your staff to use tools. There’s no point in investing in great technology if no one understands how to use it well. In addition, you’ll want to ensure that your team is technically trained to recognize signs of potential problems and understand failure reporting while conducting other maintenance tasks.

- Automate work order delegation. Depending on your maintenance staff and the types of equipment and systems you run, you may want to automate sending work orders that deal with specific malfunctions to particular technicians. This may save the middle step of a supervisor needing to make those assignments manually.

- Prioritize and schedule effectively. By using a system like a CMMS, you can prioritize the most important tasks as well as schedule technicians efficiently. For example, you can easily batch all corrective maintenance tasks on one process line or at a particular facility to reduce potential travel time to and from remote locations.

- Provide the backstory. Another advantage of using a CMMS is that all previous work, orders, questions, and failures should be available to the current technician. That individual may be able to spot patterns or note problems or issues that have repeatedly occurred despite work done.

- Stock essential tools and equipment. Be sure that your technicians have access to tool kits, testing equipment, and other basic parts and materials to complete common corrective maintenance issues. This will optimize the time they spend at each work order task.

- Take advantage of inspection opportunities. Anytime a technician works on a piece of equipment, it should be quickly checked for other potential problems. Teach your staff to notice issues and empower them to submit additional corrective orders or questions.

Corrective vs. Breakdown Maintenance

Some may wonder what the difference is between corrective and breakdown maintenance. Both work with equipment that is faulty, less than optimized, and/or broken. However, the two terms are not necessarily the same thing.

Corrective maintenance, as you just learned, is focused on rectifying and repairing faulty equipment. Breakdown maintenance is performed on equipment that is broken, faulted, or otherwise stopped in such a manner as to make the equipment nonoperational.

On the surface, the two look very similar. Let’s dive into the major difference to clear up any confusion.

How the Two Maintenance Types Differ

The biggest difference is that breakdown maintenance works on equipment that is nonoperational. Corrective maintenance takes place on equipment that is still functioning to some extent but will not function at optimal capacity without the maintenance being performed.

Corrective maintenance may very well be applied as a machine or equipment in question is still working. Breakdown maintenance may happen in an extremely short period of time, particularly if the system in question is essential.

Both types of maintenance typically happen to equipment that is still in its place or on the line. Also, both types of maintenance may be classified as emergency maintenance, depending on the situation.

Conclusion

Corrective maintenance is an important component of a company's overall maintenance program. It's critical to understand when corrective maintenance is beneficial and when it leads to inefficiencies, downtime, and other productivity losses.

The key takeaway for maintenance teams is to use solid maintenance data and analysis to pinpoint those areas where corrective maintenance can be used effectively, and when they should be a stepping stone for more preventive and predictive maintenance initiatives.

![[Review Badge] GetApp CMMS 2022 (Dark)](https://www.datocms-assets.com/38028/1673900459-get-app-logo-dark.png?auto=compress&fm=webp&w=347)

![[Review Badge] Gartner Peer Insights (Dark)](https://www.datocms-assets.com/38028/1673900494-gartner-logo-dark.png?auto=compress&fm=webp&w=336)