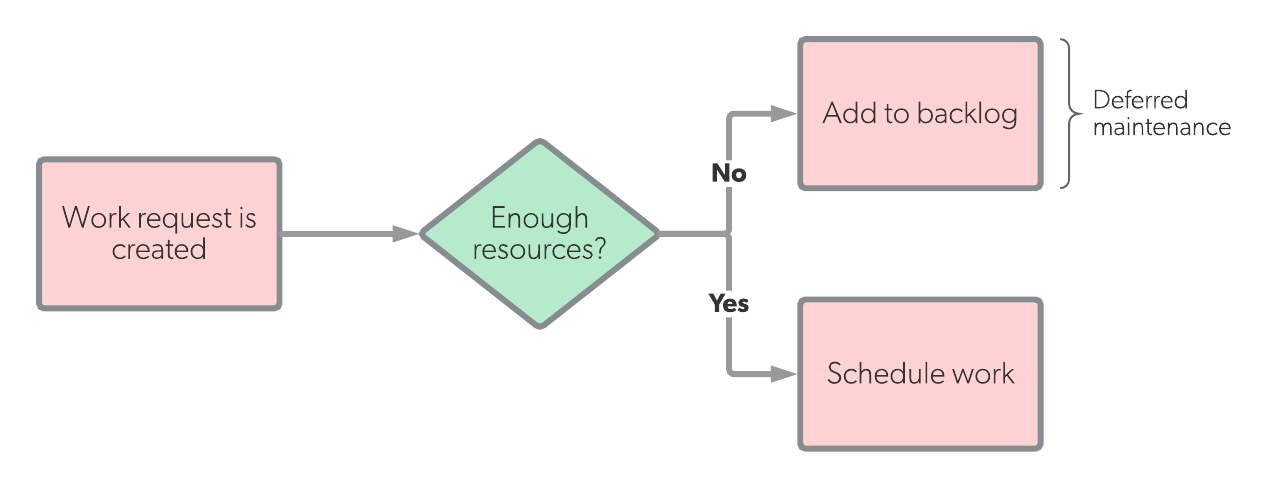

Deferred maintenance is repairs to infrastructure and assets that get delayed and backlogged because of budget limitations and lack of funding.

Deferred maintenance workflow

Overview

Compelling research shows that delaying maintenance can increase future costs and capital expenditures by as much as 600%. Despite the extraordinary consequences of delaying important repairs, deferred maintenance is common inside facilities and manufacturing plants. It also contributes to safety hazards, energy inefficiency, and reputational damage for organizations.

Deferred repairs are often put into a maintenance backlog that creates a vicious cycle. As necessary upgrades are postponed, system failures start increasing at a greater volume and frequency. This puts maintenance teams in a mode of reactivity with less focus on preventive maintenance.

How to decrease deferred maintenance

Step 1: Log maintenance activity

Centralizing data around assets, equipment, work requests, and work orders is critical for shrinking a deferred maintenance backlog. Many facility managers invest in a CMMS or EAM that captures wrench time, time to complete, maintenance costs, and warranties—all helpful inputs when running audits and making ROI cases.

Step 2: Conduct an audit

Once important data is gathered, an audit helps you understand the scale of maintenance-related issues by answering a series of questions:

- Is there equipment with warranties that are about to expire?

- Has certain equipment failed more frequently? Were the failures unexpected and unpredictable?

- What poses a safety threat? What is impacting staff? What is impacting production of goods or services?

- The answers to these questions will help you answer the most important question: If you had unlimited budget and resources, what is the complete list of repairs and upgrades that you would pursue?

Step 3: Prioritize the backlog

After you answer that central question, you're unlikely to get a blank check and extra technicians. Therefore, prioritizing the backlog around a set of criteria is key.

To prioritize, separate the backlog into two main categories: 1) Immediate Attention: projects that are cited for safety violations or require repairs to return to normal operations, and 2) Delayed Attention: projects that will become critical if not addressed within a certain time frame.

Other ways to categorize the backlog are by: Cost of upgrade, Time to repair, Asset lifecycle, Location of repair, Contractor repair vs. In-house repair, and Dependencies (what will be on hold while a repair takes place).

Having multiple ways to break out your backlog will prepare you to get buy-in from different stakeholders. Everyone wants to know how the backlog impacts them versus how it impacts you.

Step 4: Start or increase PMs

Increasing preventive maintenance tasks (PMs) is a surefire way to prevent emergency maintenance and deferred maintenance from getting out of hand. Investing in a CMMS enables easy PM scheduling with calendar views and automated reminders. It also comes with advanced features that include customized checklists and runtime-based PMs based on meter readings.

Step 5: Secure additional budget

Getting additional budget is easier if you can show where your current budget is allocated. After you implement a system that helps you show this, you need to convince higher-ups that increasing short-term profits or budget savings costs more in the long run. Industry-wide benchmarks show that deferred maintenance compounds by 7% per year.

Securing budget should not be a one time exercise. Getting other departments involved in your maintenance operations and strategy on an ongoing basis goes a long way. A survey by UpKeep shows that maintenance teams that have procurement interact with their CMMS are 28% more likely to secure additional budget.

Example of deferred maintenance

The National Parks Service (NPS) relies on funding from the United State’s federal government. Because the federal government must allocate its budget to hundreds of different areas, deferred maintenance is inevitable for the NPS.

In 2017, the NPS said deferred maintenance totalled $11.6 billion. Repairs and maintenance were delayed for everything from bridges and tunnels, to monuments and amphitheaters. However, the NPS says its receiving additional funding in 2019 to reduce deferred maintenance to a manageable level.

One of the reasons the NPS is receiving this additional funding is because of its rigid process for identifying and reporting deferred maintenance. NPS workers conduct condition assessments and log maintenance data to streamline year-end reports for the NPS’s 75,000 constructed assets. These reports help the NPS get buy-in for additional funding from the Office of Management and Budget, congress, and other areas of government.

Conclusion

While deferred maintenance is inevitable, taking a multi-pronged approach is critical to prevent a backlog that’s impossible to manage. Stewarding your organization to the forefront of solving this challenge will provide costs savings, better safety, and a larger role in planning for the future.

![[Review Badge] GetApp CMMS 2022 (Dark)](https://www.datocms-assets.com/38028/1673900459-get-app-logo-dark.png?auto=compress&fm=webp&w=347)

![[Review Badge] Gartner Peer Insights (Dark)](https://www.datocms-assets.com/38028/1673900494-gartner-logo-dark.png?auto=compress&fm=webp&w=336)