Both preventive maintenance (PM) and reliability-centered maintenance (RCM) have the same bottom-line goal: They are both designed to increase asset reliability and lifespan by creating a maintenance system of scheduled work. Both typically plan and schedule maintenance tasks in advance, with the exception of tasks designated for run-to-failure maintenance. Maintenance tasks are then completed on that predetermined schedule, which may be set by time, usage, or performance triggers.

The main difference between preventive maintenance and reliability-centered maintenance is in the uniqueness of the schedule and associated maintenance tasks. Preventive maintenance is often generalized across a large number of assets while reliability-centered maintenance takes a deep and specific look at each individual piece of equipment to create a schedule unique to only that piece of equipment.

Differences Between Preventive Maintenance and RCM

| Preventive Maintenance | Reliability Centered Maintenance | |

|---|---|---|

| Definition | Preventive maintenance (PM) is a type of proactive maintenance that keeps assets in good order by scheduling tasks at specific intervals or dates. | Reliability centered maintenance (RCM) is a process for figuring out the level of necessary maintenance for a specific piece of equipment and then designing a unique maintenance schedule. |

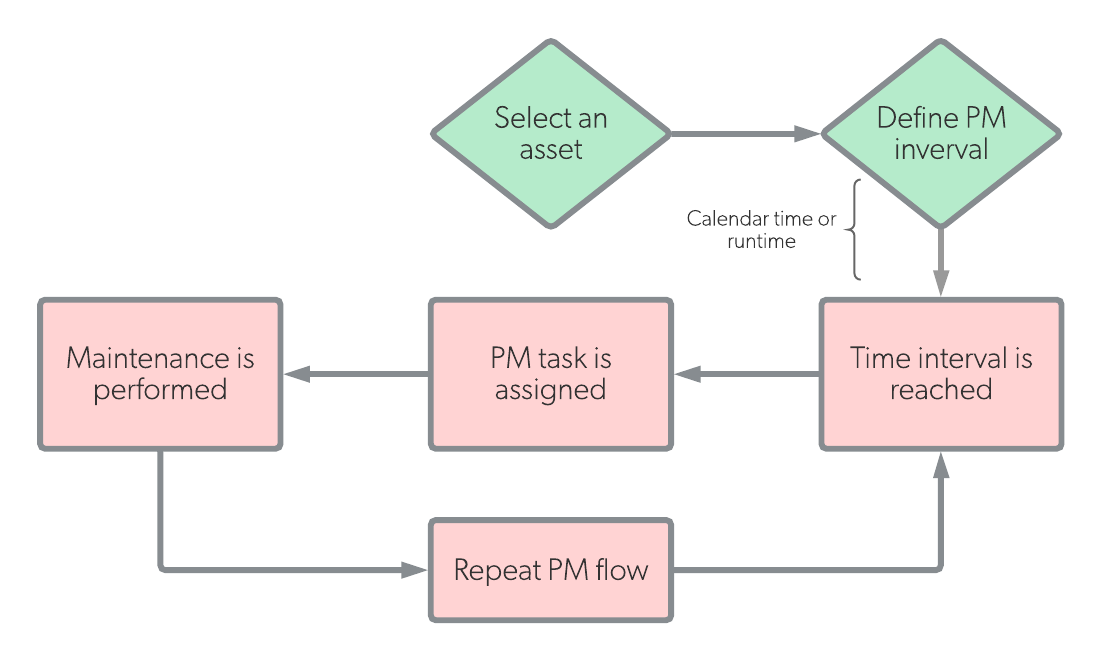

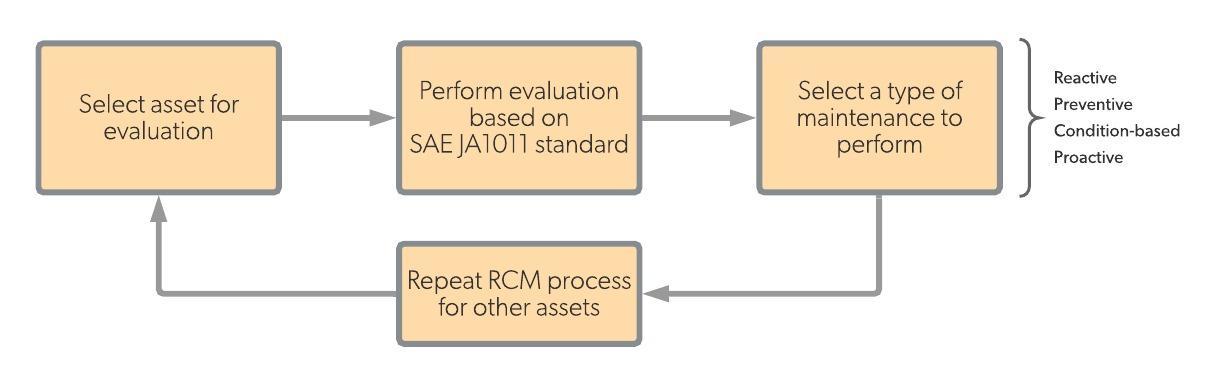

| Workflow |  |

|

| Trigger | Time | Based on individual asset needs (can be time, parameter, downtime trigger) |

| Cost | Low | Medium/High (startup cost) |

| Cost Savings | 12% to 18% [1] | 20% to 70% (dependent on implementation) [2] |

| Resources Needed |

|

|

| Pros |

|

|

| Cons |

|

|

| Use Case | An organization wants to decrease unplanned | An organization uses a complex asset that’s built |

[1] Types of Maintenance Programs by the Department of Energy, O&M Best Practices Guide, Release 3.0

[2] The ROI of RCM by Plant Services

How Do Work Flows Differ?

Although both preventive maintenance and reliability-centered maintenance have the same end goals, they approach assigning maintenance tasks a bit differently.

In a preventive maintenance program, a business selects a particular asset and defines a specific time interval between maintenance tasks. For example, one machine may require lubrication on a monthly basis. Once 30 days pass, a work order to oil that machine is generated. The maintenance technician performs that task and records that the lubrication has been conducted. If a CMMS program is being used, the data is captured and the task will appear as a work order after another month.

In a reliability-centered maintenance program, however, an asset is selected for evaluation and studied adhering to industry standards. Based on the asset and its role within the organization, the company selects the best type of maintenance program for that machine or piece of equipment. This may be a reactive maintenance, preventive maintenance, condition-based maintenance, or proactive maintenance program. Once that specific program has been selected, the company can move on to repeating the reliability-centered maintenance process for another critical asset.

How Are Both Programs Implemented?

A preventive maintenance program simply establishes a maintenance schedule based on experience, manufacturers’ suggestions or recommendations found in a manual, or equipment usage. Work orders are scheduled at appropriate intervals, and maintenance technicians complete the work when they appear on their daily task list.

A reliability-centered maintenance program focuses its implementation based on an evaluation of seven key areas. These areas examine the expected performance of the asset, how it could fail to perform, all the failure modes, their causes, their consequences, how failures can be predicted, and what actions should be taken to prevent failure.

Seven Questions for an RCM Program

Since reliability-centered maintenance programs are much more involved than preventive maintenance programs, here’s a careful look at the seven questions that programs should ask when establishing a reliability-centered maintenance program.

Here are the critical areas to evaluate, according to Reliable Plant:

-

How Does a Critical Asset Meet Current Needs?

In a nutshell, a business should look at a piece of equipment and understand what it was made to do and how it actually performs on a day-to-day basis. For example, a machine is designed to produce 500 widgets in an hour but tends to break down once per month if it runs during a single 8-hour shift every workday. Perhaps there is a night shift that doesn’t use this piece of equipment. When the asset breaks, it takes two hours to repair it. Having this basic failure data can help an organization schedule repairs before production halts by planning maintenance during those night-time, off-operation hours or by determining reasons for failure.

-

How Can This Asset Fail?

This is an exercise in determining possible scenarios or failure modes. An older piece of equipment might fail due to age. An asset operating outdoors may succumb to extreme weather conditions. If a technician makes an error while operating an asset or there is a manufacturing mistake in the product, that can also result in equipment failure.

-

Why Did Each Failure Occur?

After you identify your list of failure modes, go back and think about the reasons for the failure. Be sure to keep asking the question, “Why did this happen?” until you get to the root cause of each failure mode. For example, if a machine breaks down because a component locks up, why did it lock up? If it wasn’t lubricated, why wasn’t it oiled on time? If that was because the oil was unavailable, why was it unavailable? Perhaps a purchasing individual forgot to restock? Why did that individual forget? Perhaps the company’s computer system shows that the oil is in stock erroneously. Fixing that data discrepancy will resolve the root problem.

-

What Happens After the Failure?

This step is critical in assigning the proper maintenance program to each asset. You’ll want to understand clearly what happens if an asset fails to make decisions about how much you’ll spend to prevent that failure.

-

What Are the Consequences of the Failure?

For example, if there are no terrible consequences to a failure, it's not worth the time and money to establish a maintenance program to prevent that failure. The classic example is an office lightbulb. When it “fails” or burns out, you simply change it. It makes no sense to routinely check whether the lightbulb needs changing, nor to change it every month while it’s still working just fine. However, some failures may result in accident or injury to workers, environmental damage, or significant production loss. Failures that result in major consequences or losses must be avoided as much as possible.

-

What Can You Do to Prevent These Failures?

This step is where reliability-centered maintenance all comes together. You’ll now take each asset, its failure modes, the root causes and the consequences of each failure together to select the right maintenance approach. For those assets that generate failures with no significant consequences, you should opt for a run-to-failure plan. In cases where it's clear that regular maintenance tasks can minimize failures over time, a preventive maintenance plan would be appropriate. And, finally, in cases where a failure would have dire safety or production consequences, you may want to implement a more sophisticated plan such as a predictive maintenance program or a conditioning-monitoring program.

-

When Is It Time to Replace Your Equipment?

If you find that some of your assets are simply no longer worth maintaining, you may choose to run them to failure. In the meantime, you may want to invest in new equipment to replace that older asset and prepare it to take over the task. Perhaps both the old piece and new piece of equipment can run simultaneously to keep your uptime higher, and then the replacement can take over once the original machine dies.

What Are the Costs of Each Approach?

In general, a preventive maintenance system is easier and less expensive to implement initially. It simply involves putting your critical assets on a time or usage-based schedule. If you've already invested in a CMMS solution, setting up a preventive maintenance system is really about entering asset data. Reliability-centered maintenance programs, however, can have a large upfront cost because of the process required to study each critical asset. In addition, a unique maintenance program is created for each asset.

What Are the Cost Savings Associated with Each Program?

According to the O&M Best Practices Guide of the Department of Energy, most preventive maintenance programs can save companies between 12 percent and 18 percent of their operating costs. The cost savings realized by a reliability-centered maintenance program is heavily dependent on the quality of implementation. Cost savings may range anywhere from 20 percent to 70 percent, as reported by Plant Services in its article "the ROI of RCM".

Although the cost of a reliability-centered maintenance program is high initially in order to conduct the evaluation and assessment, it’s the most optimal maintenance program over the life cycle of the asset. A reliability-centered maintenance program can choose between run-to-failure (RTF), preventive maintenance and condition-based maintenance (or PdM), selecting the best program for the asset. As a result, it should result in the lowest overall costs when you incorporate reduction in production downtime and a decrease in other maintenance costs.

What Are the Advantages and Disadvantages of Each?

The advantages of a preventive maintenance program include the fact that, in general, they are an improvement over emergency maintenance. They are also generally faster, simpler, and easier to create and put into practice. On the other hand, reliability-centered maintenance can potentially be the most efficient overall maintenance strategy. When implemented well, a company can achieve significantly lower overall maintenance costs and increased production as a result.

Disadvantages of a preventive maintenance program can include the risk of over-maintaining your equipment by servicing it too frequently, which can be very labor-intensive and expensive for a company. Resources may be wasted in performing maintenance tasks that are not yet required. The most significant disadvantage in a reliability-centered maintenance program is the high upfront cost and the longer amount of time that's required to achieve results.

What Resources Are Needed for Each System?

To implement a preventive maintenance program, a company must have some sort of maintenance software they can use to schedule work orders. A CMMS solution can be an excellent investment because of its ability to integrate a wide variety of maintenance functionality that includes scheduling as well as providing comprehensive analytics and reports. Large organizations may need to hire a maintenance scheduler to prioritize and assign incoming work orders. Finally, you'll want to either create or locate preventive maintenance checklists for each of the assets that you'll be including your program.

To effectively implement a reliability-centered maintenance program, companies may want to invest in maintenance software that can provide scheduling capabilities for unique pieces of equipment as well as more advanced capabilities like predictive maintenance functions.

A wide variety of sensors are now available that can measure things like temperature, humidity, mileage, and liquid levels as well as other condition-based monitoring hardware and software. Businesses may find it helpful to assign acceptable ranges for a particular piece of equipment. If an asset falls outside the appropriate range, an alert can be sent automatically to the maintenance team so that a work order can be generated. Maintenance schedulers may also be needed as well as preventive maintenance checklists. Having a reliability engineer on the team who is trained in conducting the actual reliability-centered maintenance evaluation is also essential.

What Are Use Cases for Both Programs?

Organizations that want to reduce the costs associated with unplanned or emergency maintenance may benefit most from a preventive maintenance program. These may be businesses that are moving away from manual or paper-based maintenance systems.

Businesses that have some historic maintenance data and experience with their existing equipment may have an excellent foundation for establishing a preventive maintenance program. Historic data and operational experience tends to move companies toward more optimal situations. For example, if a company knows that particular failure modes already exist with existing equipment, they will be able to translate this data into a preventive maintenance program more quickly and for a lower initial investment.

Those companies that want to minimize the overall life cycle costs of their equipment in the long run may prefer a reliability-centered maintenance program. New critical assets that have a high upfront cost and play an important role in a production line or other operational part of the business may be the perfect candidate for a reliability-centered maintenance program. If the equipment is new and not in operation anywhere else in the company, the business starts with a “blank slate” and can begin by anticipating expected failure modes based on industry standards or best practice data.

Think Longer Term

Both preventive maintenance and reliability-centered maintenance programs help organizations improve their equipment performance, streamline maintenance tasks, and reduce downtime. Although preventive maintenance can stand alone, it can also be one component of reliability-centered maintenance.

The main difference between the two approaches is that preventive maintenance is easier and faster to implement and uses a time- or usage-based schedule. Reliability-centered maintenance takes more upfront investment and time to determine a unique maintenance plan for each piece of critical equipment, but in the long-run, may be a more cost-efficient approach to ongoing maintenance of assets throughout their lifetime.

If you're interested in learning more about preventive maintenance, check out our Ultimate Guide to Preventive Maintenance by clicking the banner below!

![[Review Badge] GetApp CMMS 2022 (Dark)](https://www.datocms-assets.com/38028/1673900459-get-app-logo-dark.png?auto=compress&fm=webp&w=347)

![[Review Badge] Gartner Peer Insights (Dark)](https://www.datocms-assets.com/38028/1673900494-gartner-logo-dark.png?auto=compress&fm=webp&w=336)