Routine maintenance are maintenance activities such as regular inspections or machine servicing. Routine maintenance is done on a regular basis, whether that be daily, weekly, monthly, or yearly. Routine maintenance is an important part of keeping systems up to date and functional.

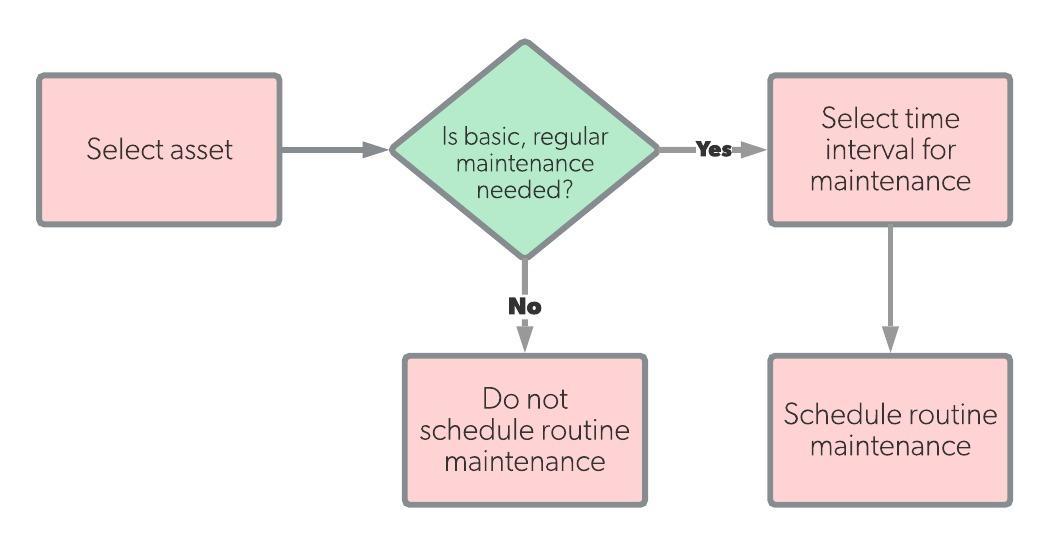

Routine maintenance workflow

Overview

Routine maintenance tasks are small and simple in nature and only require basic maintenance skills to perform well. They may be completed daily, weekly, monthly, quarterly, or annually. Companies that invest in routine maintenance can extend the life of their assets, reduce emergency maintenance, and keep their production lines or facilities up and running more consistently.

Routine maintenance is a type of preventive maintenance and also a key part of total productive maintenance in which machine operators perform small maintenance tasks to increase the reliability of the machines they use every day.

How routine maintenance decreases downtime

Routine maintenance is designed to help keep equipment, machines, and buildings operating optimally. If a particular piece of equipment needs lubrication, it may work at a slower rate and reduce the efficiency of an entire line. If dirt interferes with a certain component, an entire production line can be shut down until the problem is identified. Lubricating and cleaning equipment on a regular schedule prevents such problems.

In addition, routine maintenance can be scheduled on a daily basis, allowing a company to maximize the use of its maintenance resources. For example, if maintenance technicians move from one emergency work order to another, they may have to travel between locations, gather different tools and equipment, or simply switch mental gears from one problem to the next. A maintenance worker performing routine maintenance can clean, inspect, and adjust many items on a single piece of equipment much more quickly.

Examples of routine maintenance

Workers who perform routine maintenance for an apartment complex or other residential building are responsible for cleaning shared areas, inspecting and cleaning units when residents move in or out, or changing filters or other components in the HVAC system.

Routine maintenance in a factory setting involves lubricating, cleaning, and adjusting machines, replacing equipment parts on a schedule, inspecting certain components, or performing conditioned monitoring exercises.

Maintenance technicians who work for a municipality perform routine maintenance throughout a city. This includes trash removal, landscaping, and building walkthroughs to check for busted ballasts and burnt bulbs.

Benefits of routine maintenance

Routine maintenance prevents larger problems from occurring. Taking good care of equipment, machines, and facilities extends their overall life as well as keep them performing at their best. Routine maintenance gives technicians an opportunity to regularly “lay their eyes on” important components of a production line or specific system as well as a chance to catch any other potential problems that are lurking.

In addition, most maintenance technicians assigned to perform routine inspections, cleaning, or adjustments are entry-level or relatively new to a particular maintenance department. Routine maintenance is typically simple and straightforward and is an excellent training ground for a new technician to learn about a particular facility, business, or complex.

How to maximize routine maintenance

Routine maintenance provides an excellent return on investment considering the reduction of emergency work orders, increased efficiency of equipment, and fewer equipment replacement needs.

In order to maximize the benefits of routine maintenance, provide training and education to maintenance technicians about how to clean, inspect, lubricate, service, and adjust equipment, components or systems. Create a comprehensive maintenance checklist for each piece of equipment or machinery that requires routine maintenance, and research the industry standard for lubricating, replacing, or cleaning to ensure the routine maintenance is appropriate.

![[Review Badge] GetApp CMMS 2022 (Dark)](https://www.datocms-assets.com/38028/1673900459-get-app-logo-dark.png?auto=compress&fm=webp&w=347)

![[Review Badge] Gartner Peer Insights (Dark)](https://www.datocms-assets.com/38028/1673900494-gartner-logo-dark.png?auto=compress&fm=webp&w=336)