Fleet Management Software: The Simplest Tool To Meet All Your Fleet Management and Maintenance Needs

Making sure that your fleet is operational while keeping safety up and costs down can be difficult. With UpKeep you have the ability to prioritize asset health, employee safety, and reduce downtime costs with preventive maintenance checklists.

No credit card required.

90%

Reduction in technician time spent filing work orders and locating asset information

315%

Return on Investment

$638K

Savings from avoided production downtime

Source: Study conducted through a third party through Forrester. Download the full report here.

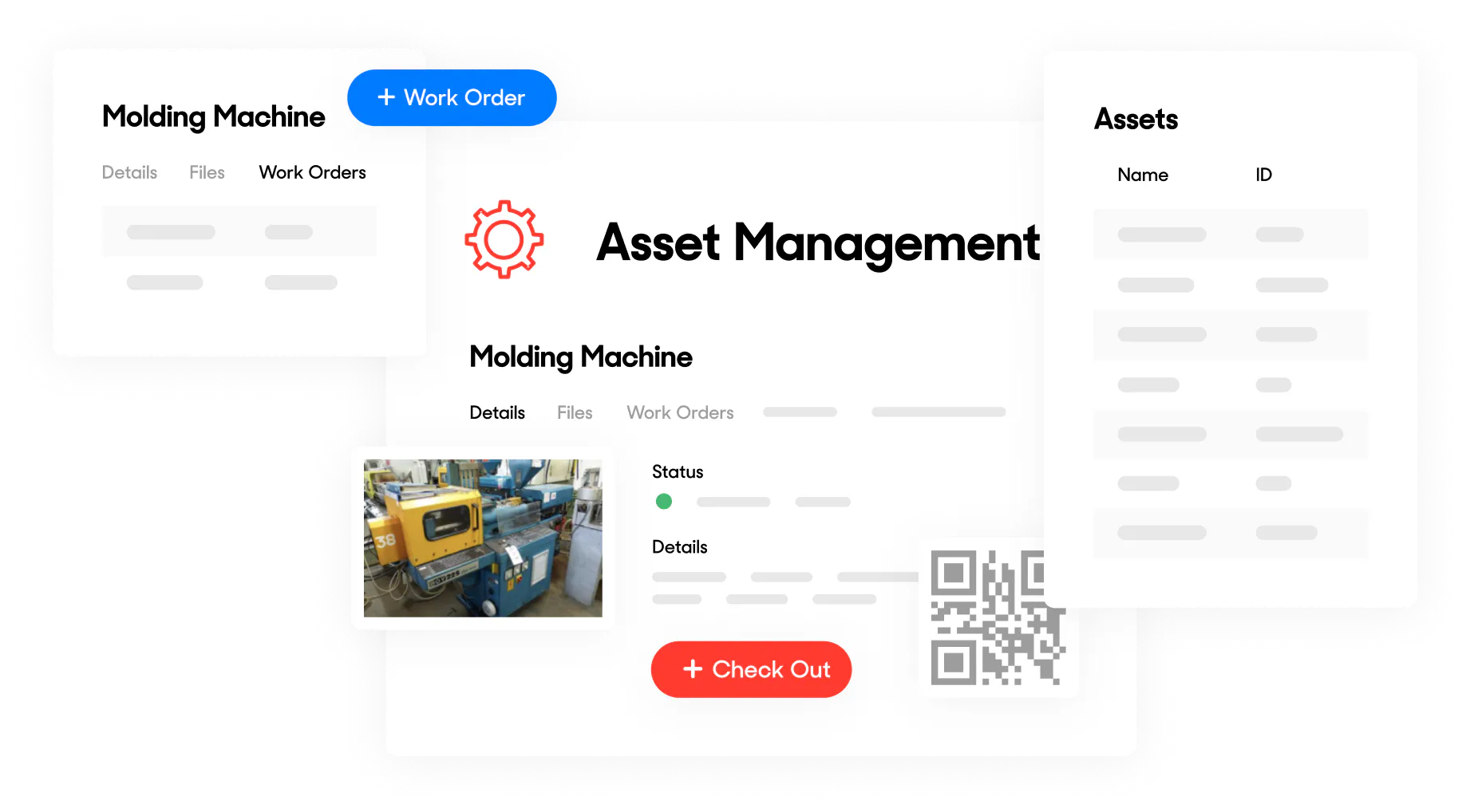

Maximize Asset Health and Fleet Maintenance on Any Street With UpKeep’s CMMS Fleet Maintenance Software

Maximize asset lifespan with runtime preventative maintenance

By combining our fleet maintenance management software with meters, you can automatically assign work orders based on runtime to ensure your vehicles are in optimal condition. After a threshold number of hours or cycles, UpKeep will automatically generate a work order for your technician of choice.

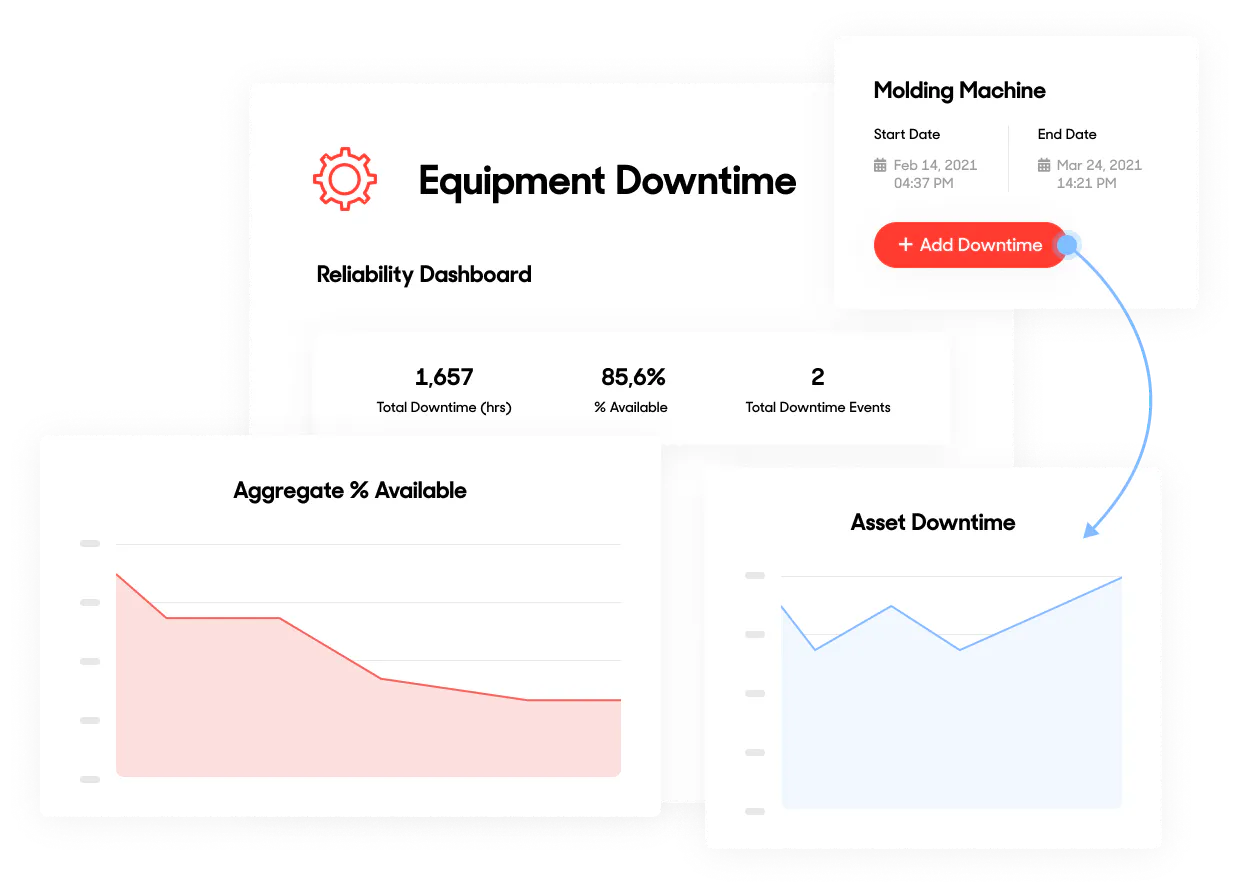

Beautiful reports to inform data-driven decisions

UpKeep Analytics gives you visibility into the trends of your fleet of vehicles month over month to help prepare for future needs. Generate outstanding data visualizations to share with management, including asset performance and health, time and cost reports, and parts consumption.

Seamless GPS and IoT integrations to ensure your fleet is running at optimal health

Easily integrate UpKeep software for fleet maintenance with Samsara, Linxup, and more to ensure your fleet is always up and running. Sync a vehicle’s location in real time so you know exactly where it is. Get fault codes and DTC alerts to trigger work orders when needed.

Explore Case Studies

Explore more case studiesLearn the Benefits of Utilizing Fleet Maintenance CMMS

If your company relies on a fleet of vehicles to get jobs done, using a fleet maintenance computerized maintenance management system (CMMS) is one of the most important things you can do.

Imagine trying to manually keep track of every vehicle involved in your company’s work. This could lead to lost time, money, and productivity due to breakdowns and general inefficiency.

Fleet maintenance software gives you many benefits, including easy ways to:

Proactively schedule maintenance tasks

Track maintenance histories

Optimize routes

Improve fuel efficiency; and

Comply with all regulatory requirements

These functions will allow you to streamline operations and reduce downtime. So fleet maintenance management software will not only make your life easier, but it will also lead to big cost savings and better safety outcomes.

Mobile Features

Mobile Features for Fleet Management Software

Capture and share fleet meter readings from anywhere.

Technicians can easily track insights on asset runtime and use them on their smartphones.

Incorporate meter readings into regular preventive maintenance on assets to maximize lifespan and ROI.

Paired with UpKeep Edge, IoT sensor meter readings are automatically recorded in UpKeep. If a reading falls before a threshold, UpKeep can automatically fire out a work order and notify the right technician to take immediate action.

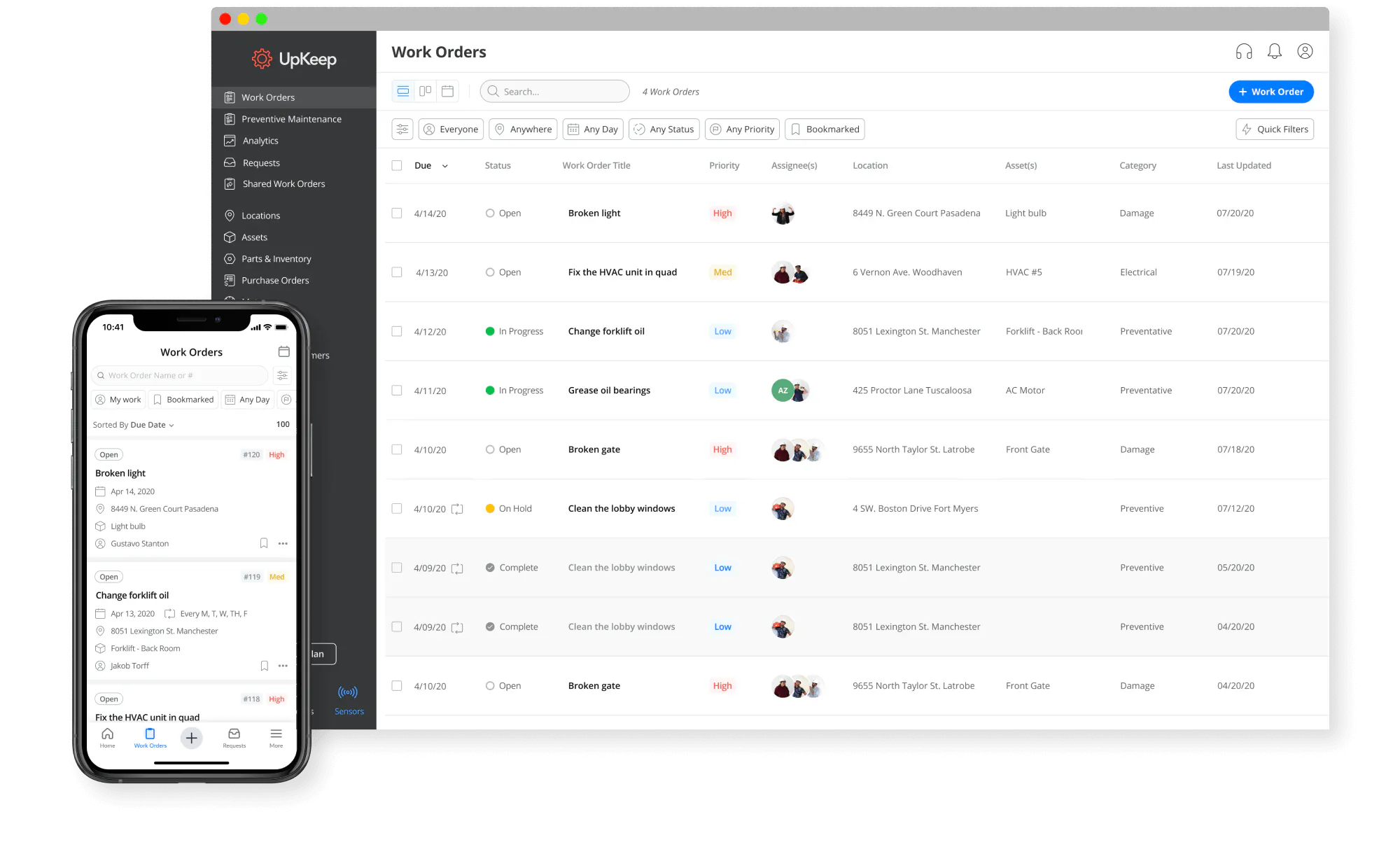

Work Orders to Reduce Equipment Downtime Costs Switchback

Easily prioritize and assign work orders for your forklifts and trucks based on priority, category, and more. Increase visibility into cost per work order and breakdown costs to better inform financial decisions and whether to repair or replace an asset.

CMMS, Maintenance Management, and Work Order Software

UpKeep is consistently rated the best inventory management software in value for money, ease-of-use, functionality, and customer support. There’s a reason UpKeep has more 5-star reviews than any other CMMS and Maintenance Software vendor.

Reduce your equipment and asset downtime by up to 26%

Extend your asset and equipment lifetime by up to 11%

Achieve up to 652% ROI by integrating UpKeep into your workflow

Improve overall facility condition with the integration of UpKeep

Trending Resources

Book

We Wrote the Book on Asset Operations!

UpKeep brought maintenance, reliability, and operations teams together in a new approach called Asset Operations Management. Now, we’ve written the book! We’re thrilled to announce the publication of Asset Operations: The Future of Maintenance, Reliability, and Operations.

Blog

Preventive Maintenance Checklist - Common Tips for Trucks and Fleets

Blog

The Top 3 Benefits of Fleet Maintenance (and Why It’s More Important Than You May Think)

Fleet Maintenance Software FAQs

Fleet maintenance software allows your company’s vehicles to run on data. Users can input asset information, schedule maintenance tasks, track repairs, monitor usage, get reminders, and generate reports. All these features work together to save you time and money.

Yes! UpKeep’s fleet maintenance CMMS can integrate with other systems such as Samsara, Linxup, and more to provide a comprehensive view of fleet operations. This allows you to always have an overview of features like GPS tracking, fuel management, and part ordering systems.

Absolutely. UpKeep allows you to scale and tailor our software to fit the needs of any size fleet. Get a demo to find out exactly how our maintenance software can work for your company.

UpKeep’s software is mobile-first, making it easy to streamline operations and asset management. It’s simple to use and easily accessible by your fleet operators.

You’ll get an amazing return on investment when you use UpKeep’s software for fleet maintenance — some companies have seen an ROI of up to 652%.

The money you put in is nothing compared to what you’ll save due to:

- Reduced maintenance costs

- Increased vehicle uptime

- Improved fuel efficiency; and

- Better overall fleet management

Book a demo or start a free trial to see just how much your initial investment can save you in the long run.

4,000+ COMPANIES RELY ON ASSET OPERATIONS MANAGEMENT

Leading the Way to a Better Future for Maintenance and Reliability

Your asset and equipment data doesn't belong in a silo. UpKeep makes it simple to see where everything stands, all in one place. That means less guesswork and more time to focus on what matters.

![[Review Badge] GetApp CMMS 2022 (Dark)](https://www.datocms-assets.com/38028/1673900459-get-app-logo-dark.png?auto=compress&fm=webp&w=347)

![[Review Badge] Gartner Peer Insights (Dark)](https://www.datocms-assets.com/38028/1673900494-gartner-logo-dark.png?auto=compress&fm=webp&w=336)