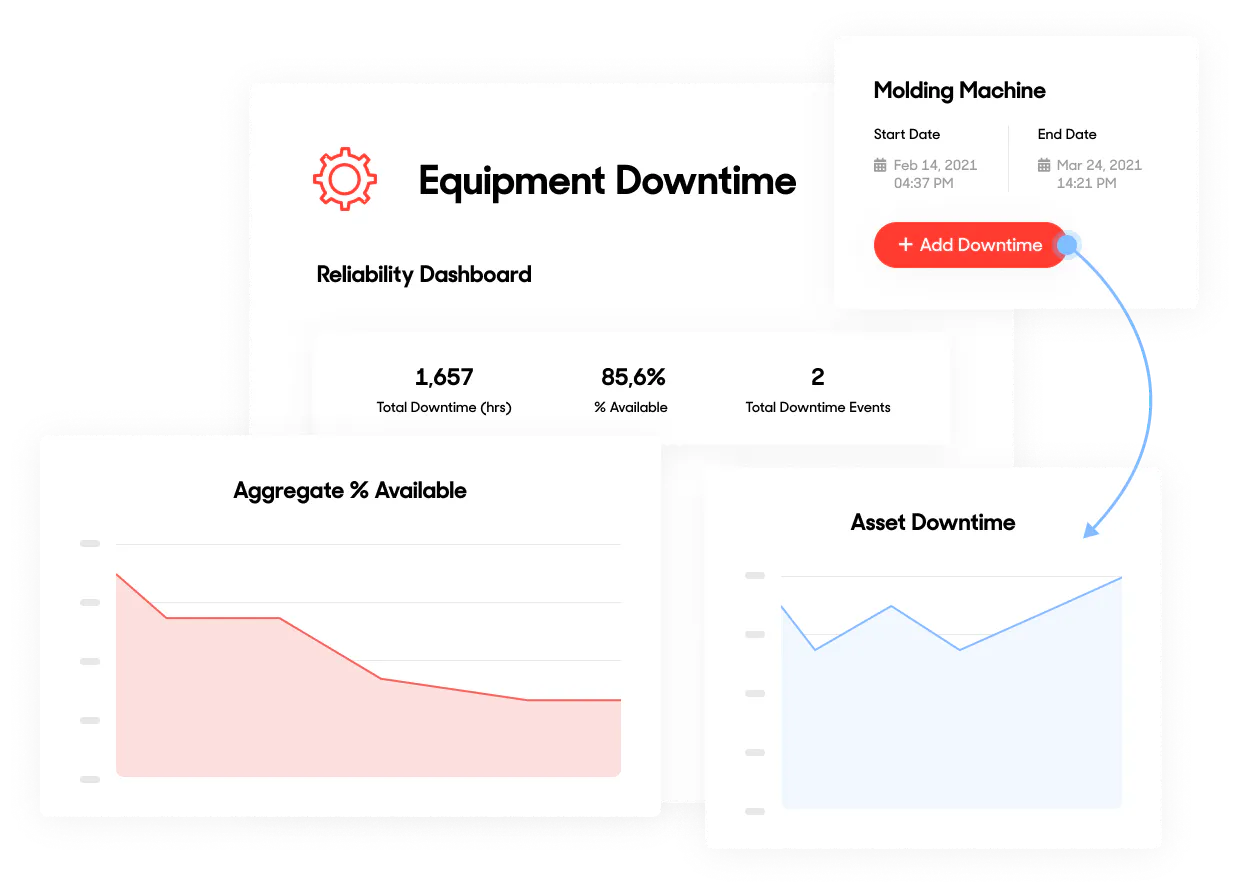

Equipment Downtime Tracking Software

Track downtime to create insightful maintenance reports, predict future equipment failures, and make data-driven decisions about repairing or replacing an asset.

Get ahead of unplanned equipment breakdowns.

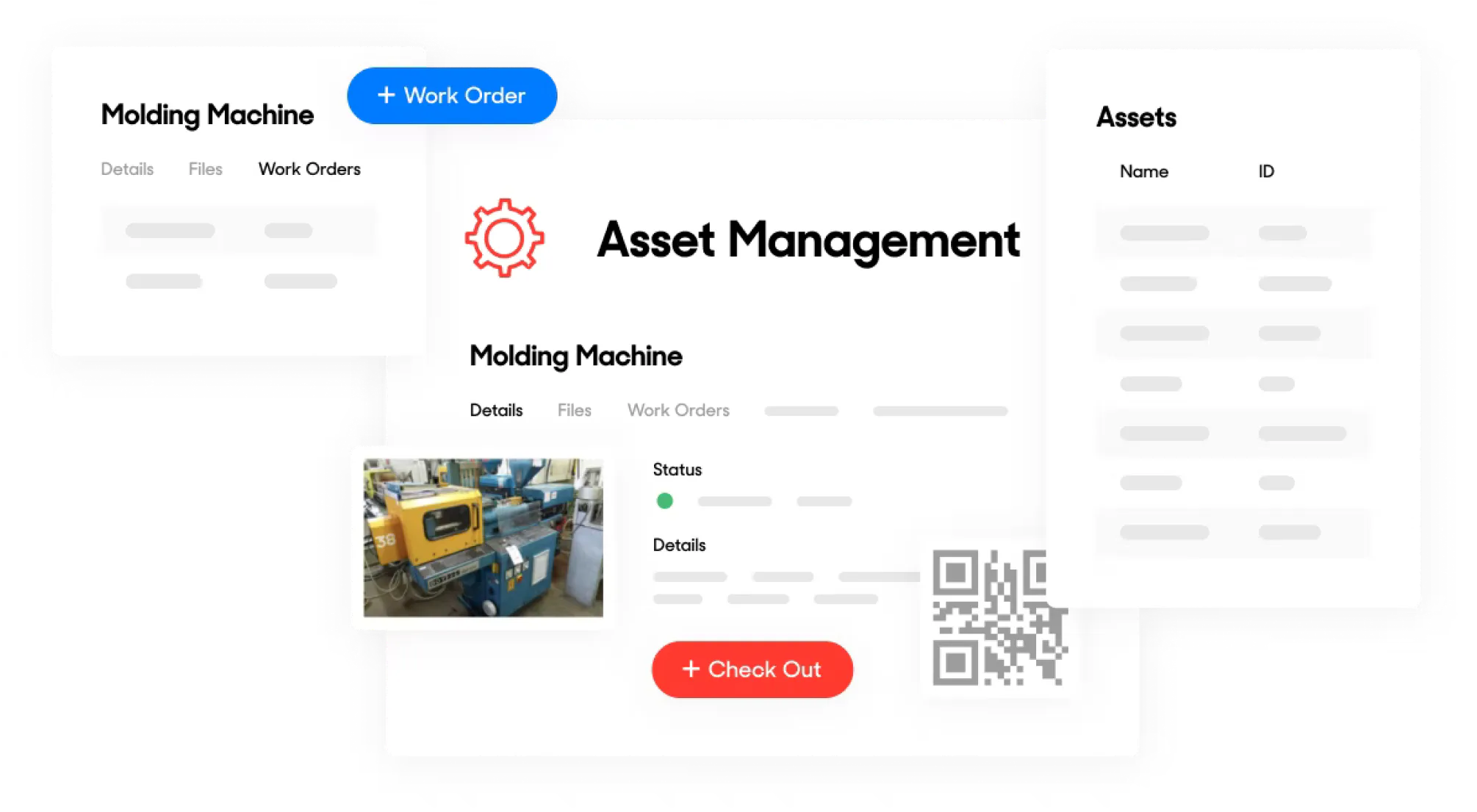

Track asset availability and downtime

Advanced reliability and downtime analytics

Better maintenance planning

Save costs with preventive maintenance

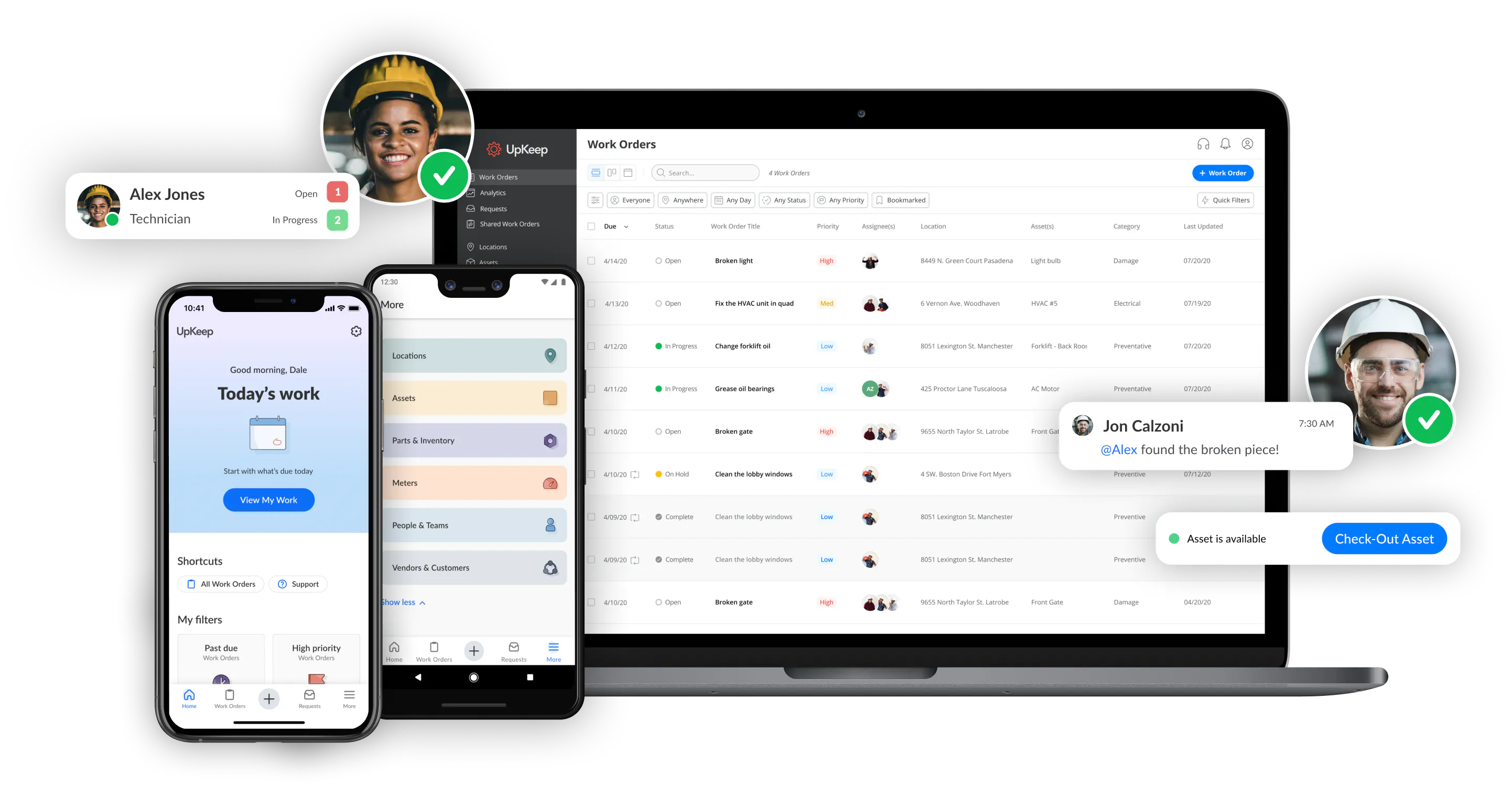

AWARD-WINNING WORK ORDER SOFTWARE

Consistently rated best-in-class.

Asset Management for Equipment That You Can Count On With Customer-Proven ROI

Bring cost and revenue to the forefront under one umbrella to look past WHAT teams are doing to the impact they are making. In this Forrester Wave™ report featuring UpKeep, a manufacturing company was able to achieve incredible results, including:

$1.4M Savings 50% Increase in preventative work to avoid production downtime

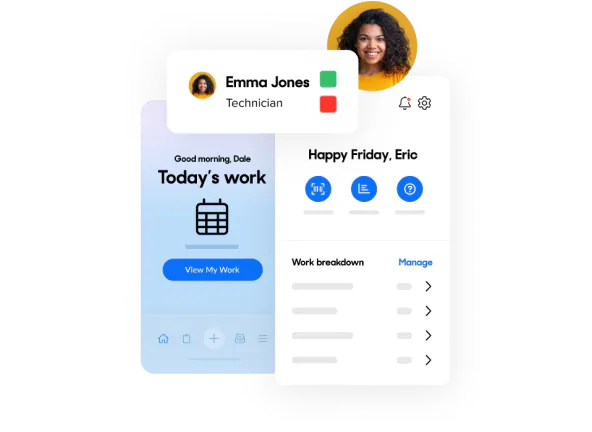

Accurately track equipment downtime to the minute with the mobile app.

- Have equipment operators mark an asset as non-operational immediately after it fails.

- They can do this at a nearby kiosk that has a tablet with UpKeep’s mobile app installed.

- Make technicians uptime-ready.

- Have technicians mark an asset as operational immediately after the repair is made and the asset is performing as expected. They can do this from their smartphone with the UpKeep app.

- Know the true cost of downtime.

- A minute of downtime for a critical asset can cause significant losses in output and revenue. Tracking downtime to the minute will lead to clearer insights and better decision making.

UPKEEP EXPERTS HERE TO HELP YOU

Incomparable Training, Implementation, and Support Ensures Your Success

We promise expedient account setup, secure data migration, professional online team training, and 24/7 customer support with our maintenance software for churches and non-profits. The Upkeep Customer Success Team works like an extension of your team, helping churches and non-profits hit their maintenance goals by providing useful resources, reliable support, and a personalized plan to help you grow with UpKeep.

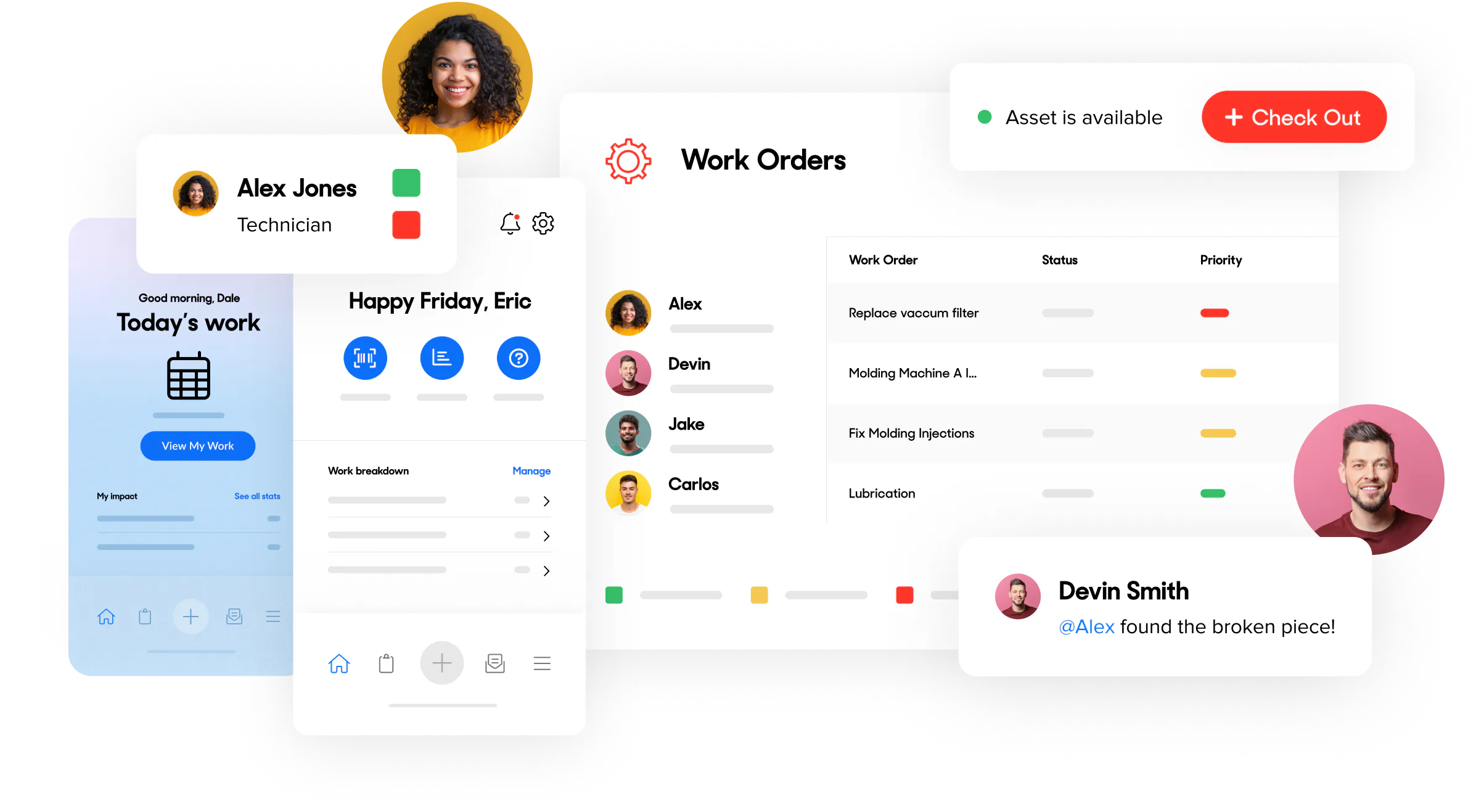

Mobile Features

Streamline Your Work Request With a Mobile Maintenance Solution

Never waste time looking for a work request. Unlimited free requesters can submit work requests and track the status of their requests.

Technicians can easily track all time spent on tasks using a timer. Reliable data collected directly from technicians' smartphones helps church and non-profit maintenance managers plan realistic PM schedules.

Reduce interruptions and accomplish more work. Replace radio chatter and phone calls with comments and updates on the status of work orders.

Maintenance Software

CMMS, Maintenance Management, and Work Order Software

UpKeep’s maintenance software for churches and non-profits is consistently rated best-in-class for value for money, ease of use, functionality, and customer support. There’s a reason UpKeep has more 5-star reviews than any other CMMS and Maintenance Software vendor.

Reduce your equipment and asset downtime by up to 26%

Extend your asset and equipment lifetime by up to 11%

Achieve up to 652% ROI by integrating UpKeep into your workflow

Improve overall facility condition with the integration of UpKeep

UpKeep experts here to help you

From expedient account set up, secure data migration and professional online team training to 24/7 customer support, we’ve got you covered. The Upkeep Customer Success Team works like an extension of your team, helping customers hit their maintenance goals by providing useful resources, reliable support, and a personalized plan to help you grow with UpKeep.

Here’s what our customers say about us…

Free Personalized Product Tour

#1 Software for Maintenance & Facility Management

Use for failure mode analysis

Make data-driven decisions

Log data automatically or manually

Prioritize preventive maintenance